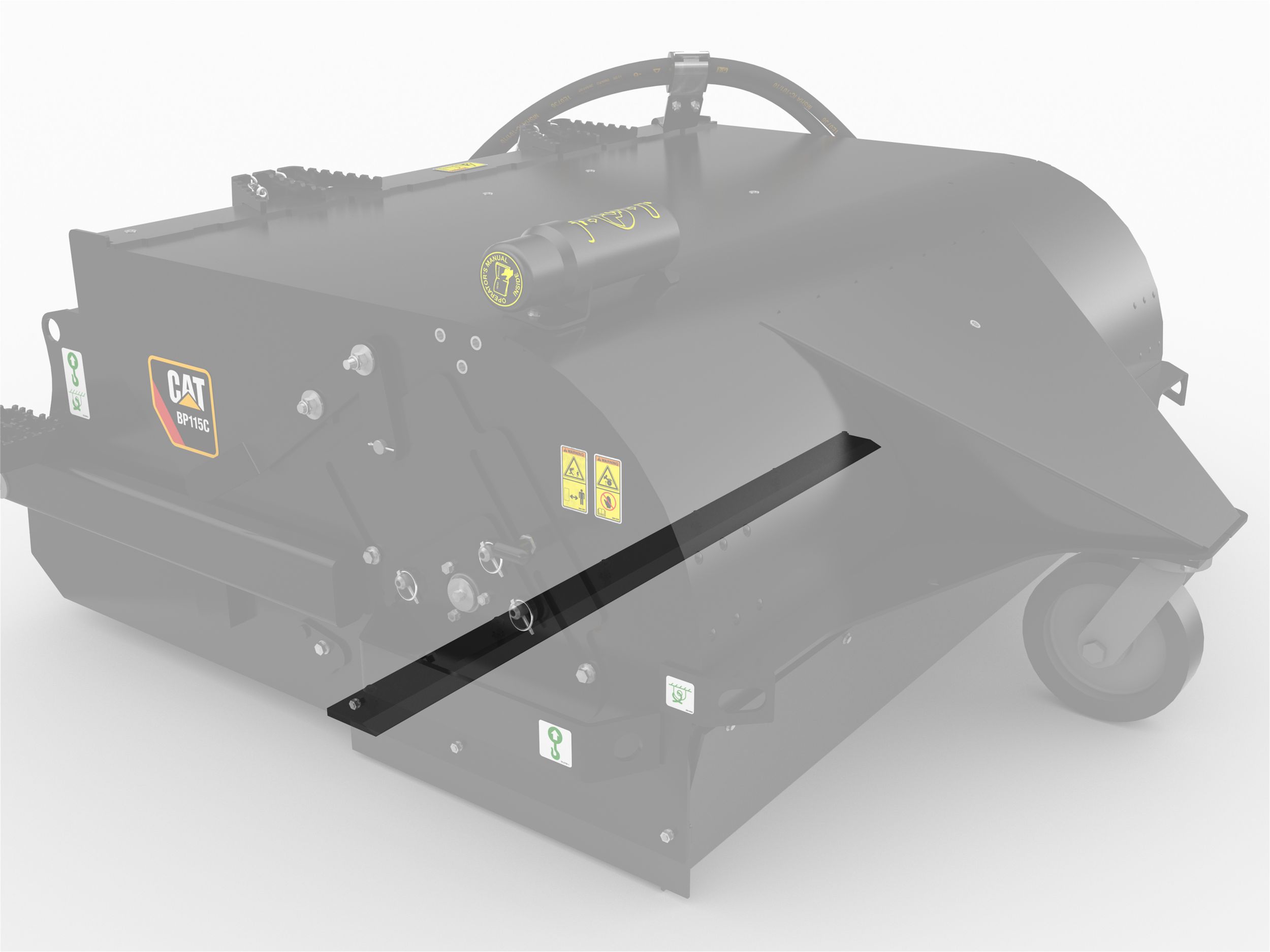

Technicial Specifications

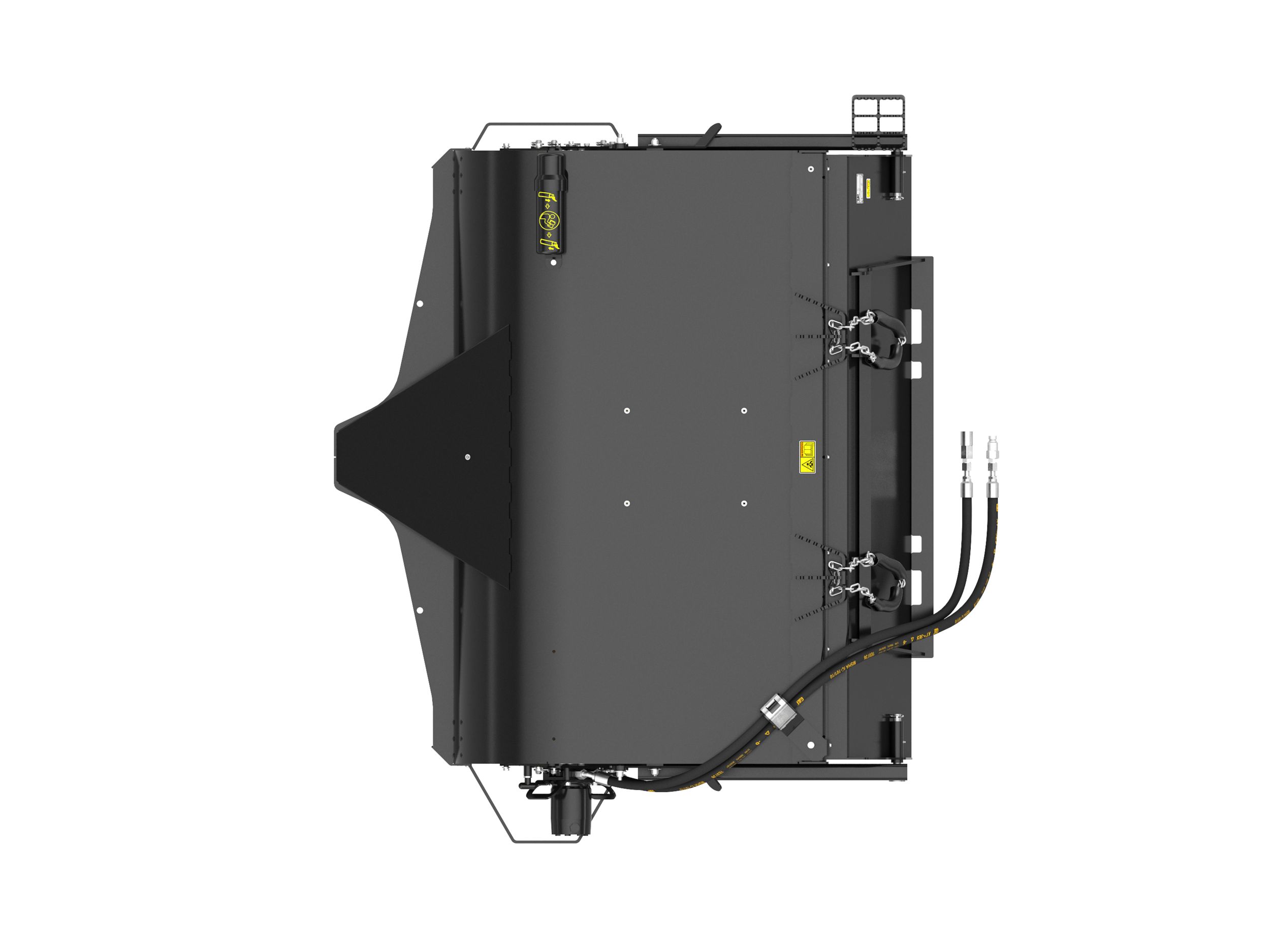

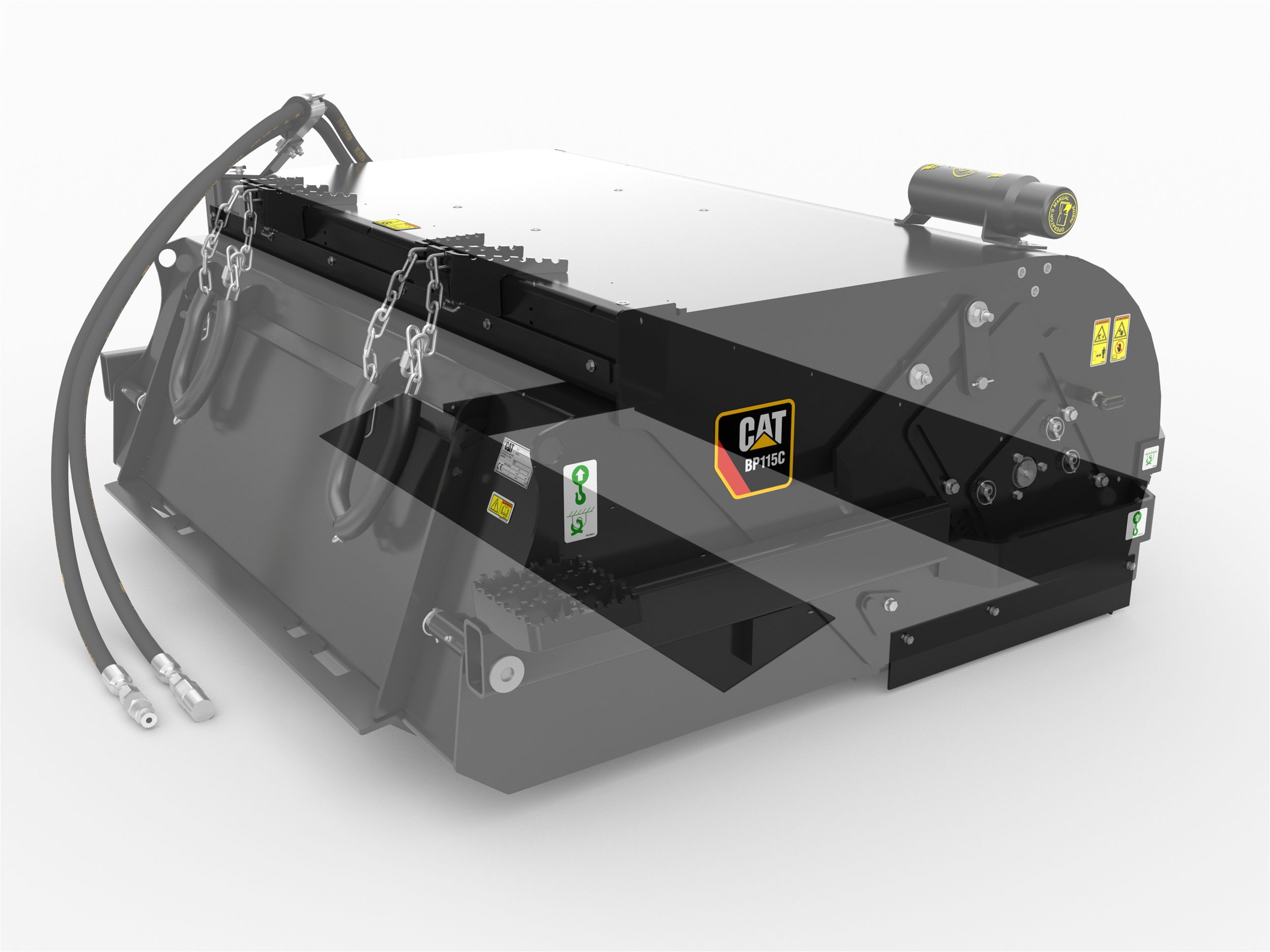

| Overall Width | 90.4 in 2295 mm |

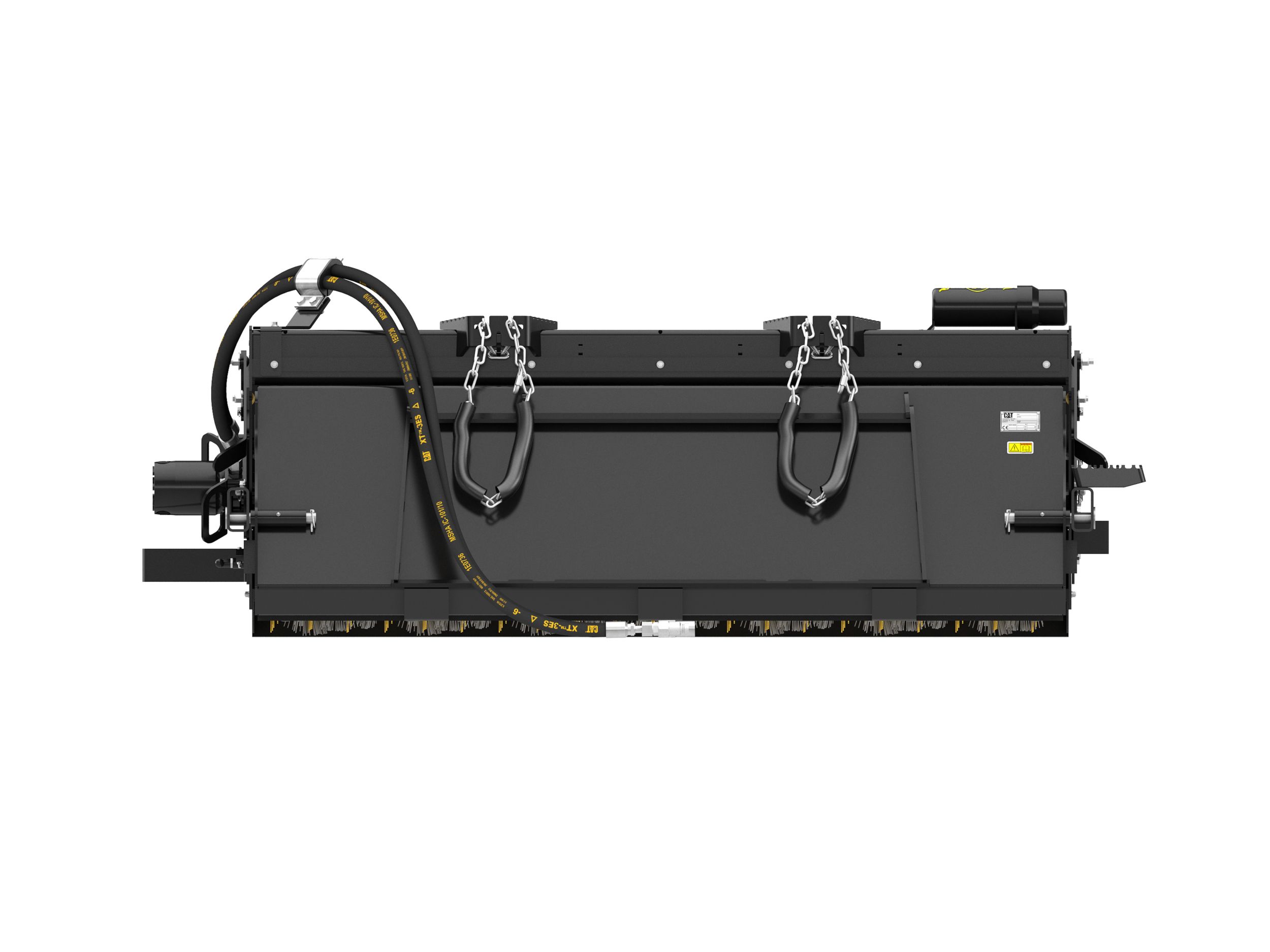

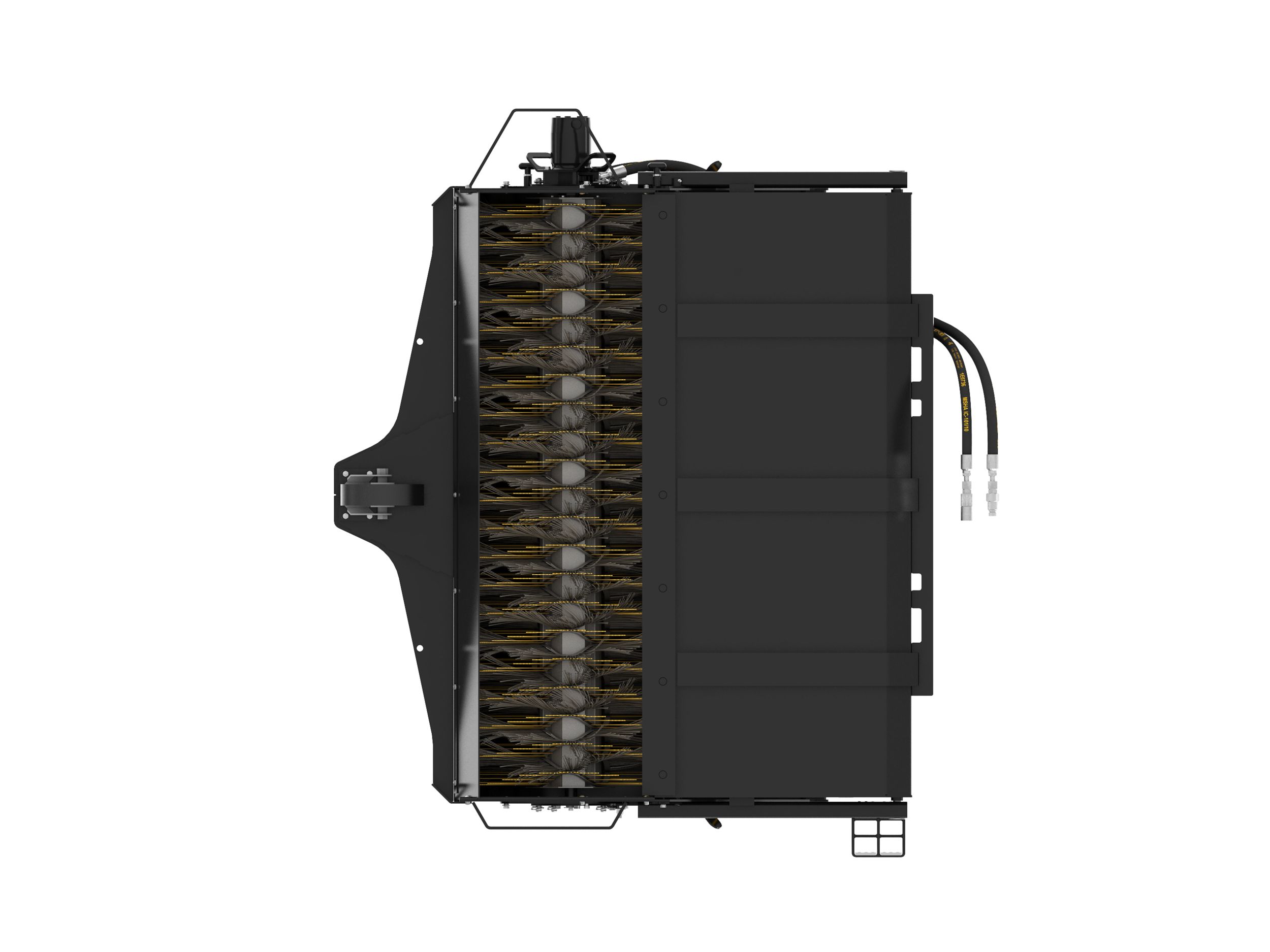

| Sweeping Width | 72 in 1829 mm |

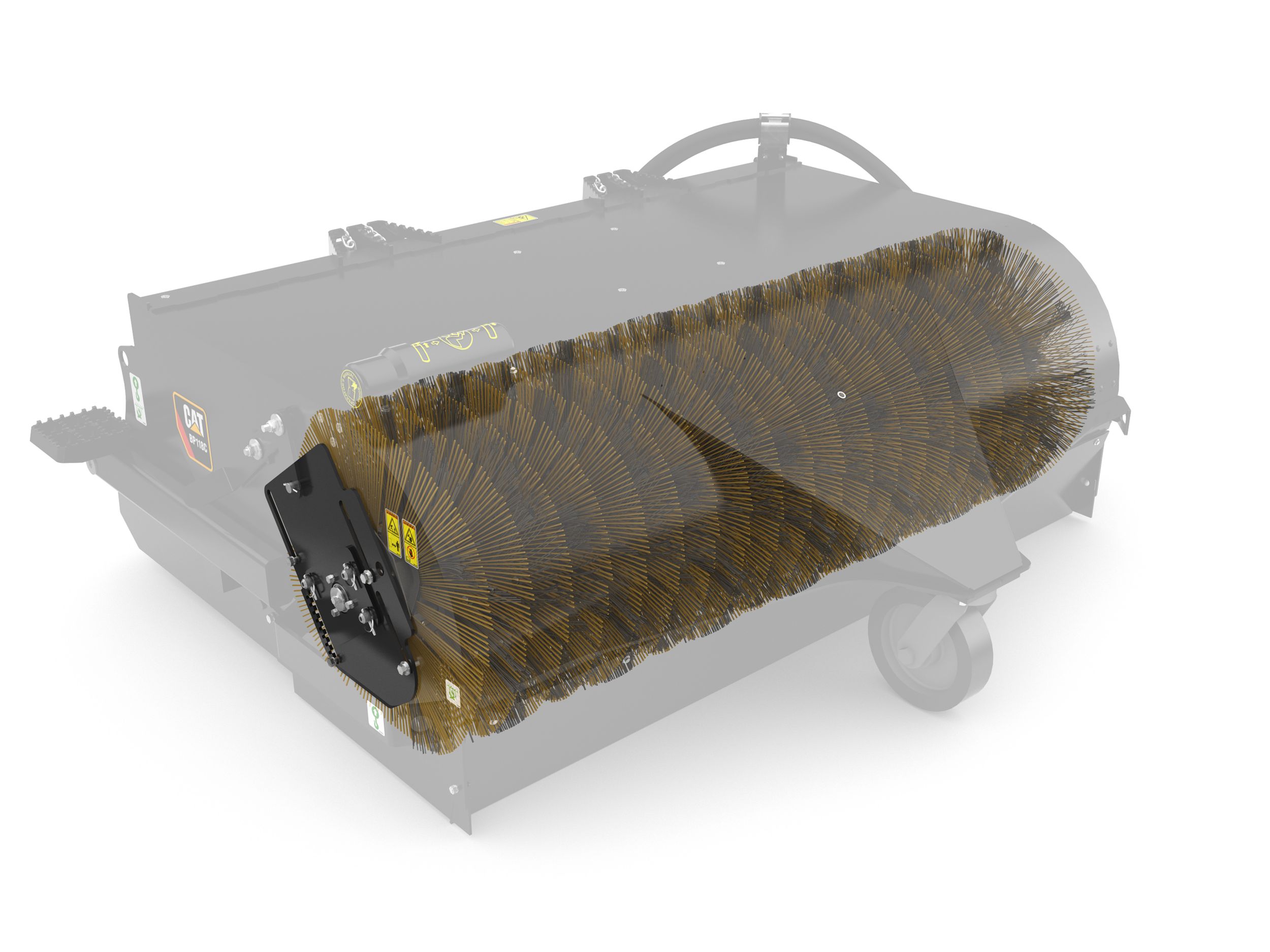

| Brush Diameter | 26 in 660 mm |

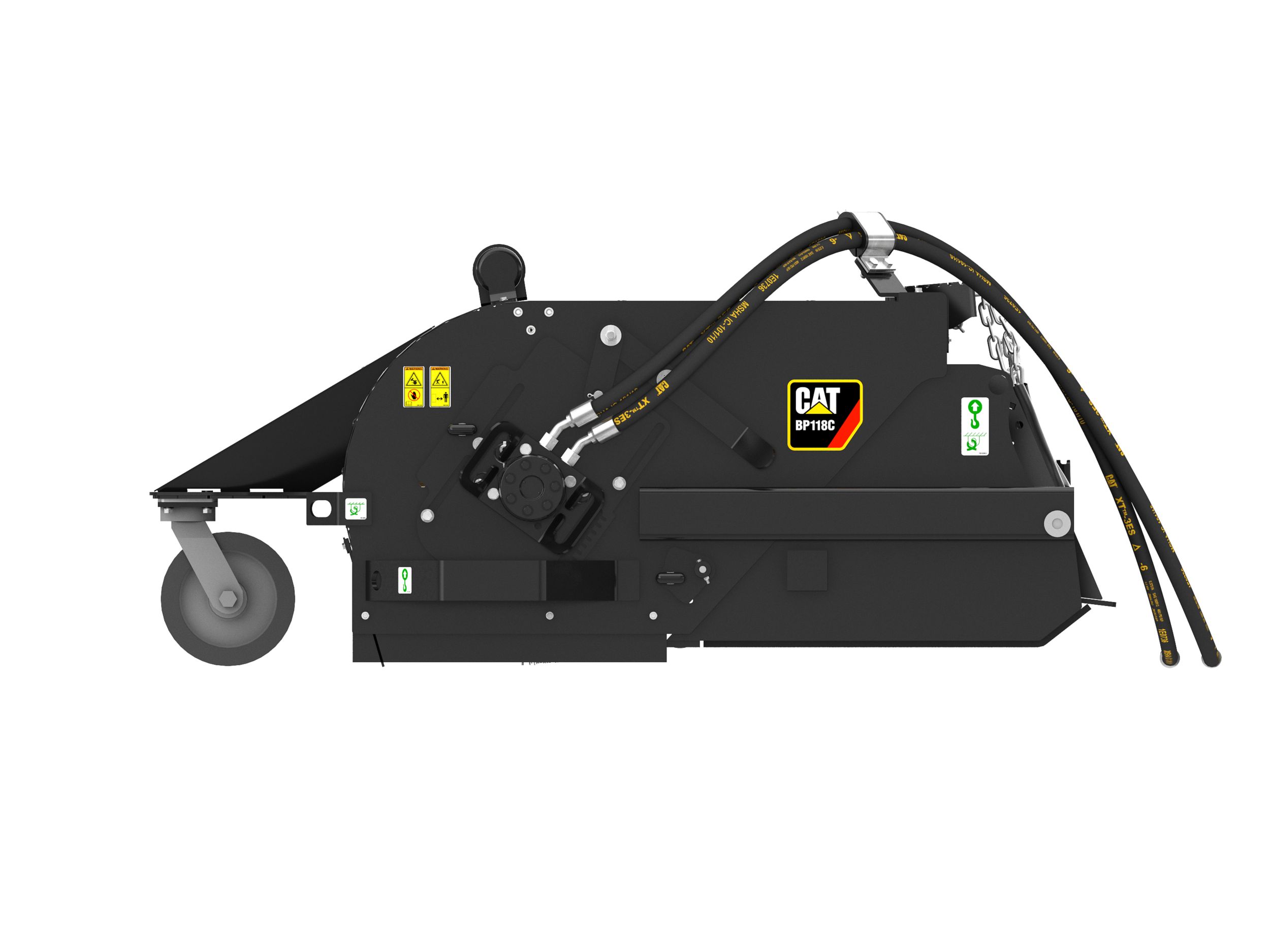

| Required Hydraulics | Standard Flow Standard Flow |

| Height | 34.3 in 872 mm |

| Length | 72.3 in 1837 mm |

| Weight | 1256.6 lb 570 kg |

| Optimal Hydraulic Flow | 42-86 L/min (11-23 gpm) 42-86 L/min (11-23 gpm) |

| Optimal Hydraulic Pressure | 145-235 bar (2100-3400 psi) 145-235 bar (2100-3400 psi) |

| Motor Displacement | 24.7 in³/rev 405 cm³/rev |

| Brush Speed at Maximum Flow | 199 rpm 199 rpm |

| Hopper Capacity | 0.6 yd³ 0.49 m³ |

| Drive Method | Direct Drive Direct Drive |