Technicial Specifications

| Gross Power - SAE J1995:2014 | 435 hp 324 kW |

| Net Power - SAE J1349:2011 | 405 hp 302 kW |

| Net Power - ISO 9249:2007 | 405 hp 302 kW |

| Engine Power - ISO 14396:2002 | 426 hp 318 kW |

| Engine Model | C15 Cat® C15 Cat® |

| Emissions | U.S. EPA Tier 4 Final/ EU Stage V/Korea Stage V and Japan 2014 or Brazil MAR-1, emitting equivalent to U.S. EPA Tier 3/EU Stage IIIA U.S. EPA Tier 4 Final/ EU Stage V/Korea Stage V and Japan 2014 or Brazil MAR-1, emitting equivalent to U.S. EPA Tier 3/EU Stage IIIA |

| Rated Speed | 1800 1800 |

| Torque Rise | 33% 33% |

| Bore | 5.4 in 137.2 mm |

| Stroke | 6.7 in 171.4 mm |

| Displacement | 927.6 in³ 15.2 l |

| High Idle Speed | 2300 r/min 2300 r/min |

| Low Idle Speed | 800 r/min 800 r/min |

| Maximum Altitude – Without Derating (Tier 4 Final/Stage V) | 9298 ft 2834 m |

| Maximum Altitude - Without Derating (Tier 3/Stage IIIA) | 9098 ft 2773 m |

| Note | Net power advertised is the power available at the engine flywheel when the engine is equipped with a fan, air cleaner, clean emissions module and alternator. Net power advertised is the power available at the engine flywheel when the engine is equipped with a fan, air cleaner, clean emissions module and alternator. |

| Operating Weight (Tier 4 Final/Stage V) | 90207 lb 40917 kg |

| Operating Weight (Tier 3/Stage IIIA equivalent) | 89186 lb 40454 kg |

| Maximum Operating Weight (Tier 4 Final/Stage V) | 92568 lb 41988 kg |

| Maximum Operating Weight (Tier 3/Stage IIIA equivalent) | 91549 lb 41526 kg |

| Transmission Type | Planetary - Powershift - ECPC Planetary - Powershift - ECPC |

| Direct Drive - Forward 1 | 4.2 mile/h 6.8 km/h |

| Direct Drive - Forward 2 | 7.5 mile/h 12.1 km/h |

| Direct Drive - Reverse 1 | 4.3 mile/h 7.8 km/h |

| Direct Drive - Reverse 2 | 8.6 mile/h 13.8 km/h |

| Pump Flow at 1800 rpm | 30.9 gal/min 117 l/min |

| Main Relief Pressure | 3771 psi 26000 kPa |

| Maximum Supply Pressure | 3495 psi 24100 kPa |

| Lift System | Double Acting Cylinder Double Acting Cylinder |

| Bore | 4.7 in 120 mm |

| Stroke | 42.1 in 1070 mm |

| Cooling System | 30.6 gal (US) 116 l |

| Engine Crankcase | 9 gal (US) 34 l |

| Transmission | 17.4 gal (US) 66 l |

| Fuel Tank | 206.6 gal (US) 782 l |

| Diesel Exhaust Fluid Tank (Tier 4 Final/Stage V) | 8.5 gal (US) 32 l |

| Differential - Final Drives - Front | 26.4 gal (US) 100 l |

| Differential - Final Drives - Rear | 29.1 gal (US) 110 l |

| Hydraulic Tank Only | 35.4 gal (US) 134 l |

| Note | Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels** up to: • 20% biodiesel FAME (fatty acid methyl ester) * • 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details. * Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel (for use of blends higher than 20% biodiesel, consult your Cat dealer). ** Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same as traditional fuels – Cat DEO-ULS™ or oils that meet the Cat ECF-3, API CJ-4, and ACEA E9 specifications are required. – Diesel exhaust fluid (DEF) that meets all requirements defined in ISO 22241-1:2006. Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels** up to: • 20% biodiesel FAME (fatty acid methyl ester) * • 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details. * Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel (for use of blends higher than 20% biodiesel, consult your Cat dealer). ** Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same as traditional fuels – Cat DEO-ULS™ or oils that meet the Cat ECF-3, API CJ-4, and ACEA E9 specifications are required. – Diesel exhaust fluid (DEF) that meets all requirements defined in ISO 22241-1:2006. |

| Front | Planetary - Fixed Planetary - Fixed |

| Rear | Planetary - Oscillating Planetary - Oscillating |

| Oscillation Angle | ±5° ±5° |

| Service Brakes | Multi Disc Wet (Enclosed) 2 WHL Multi Disc Wet (Enclosed) 2 WHL |

| Parking Brake | Drum and Shoe, Spring Applied, Hydraulic Released Drum and Shoe, Spring Applied, Hydraulic Released |

| Operator Sound Pressure Level (ISO 6396:2008) | 73 dB(A) 73 dB(A) |

| Machine Sound Power Level (ISO 6395:2008) | 113 dB(A) 113 dB(A) |

| Operator Sound Pressure Level (ISO 6396:2008)* | 72 dB(A) 72 dB(A) |

| Machine Sound Power Level (ISO 6395:2008)* | 110 dB(A) 110 dB(A) |

| Note (1) | * Sound suppression equipped * Sound suppression equipped |

| Note (2) | The machine sound power level was measured according to ISO 6395:2008. The measurement was conducted at 70 percent of the maximum engine cooling fan speed. The machine sound power level was measured according to ISO 6395:2008. The measurement was conducted at 70 percent of the maximum engine cooling fan speed. |

| Note (3) | The operator sound pressure level was measured according to ISO 6396:2008. The measurement was conducted at 70 percent of the maximum engine cooling fan speed. The operator sound pressure level was measured according to ISO 6396:2008. The measurement was conducted at 70 percent of the maximum engine cooling fan speed. |

| Note (4) | Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment. Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment. |

| Operator Sound Pressure Level (ISO 6396:2008) | 73 dB(A) 73 dB(A) |

| Machine Sound Power Level (ISO 6395:2008) | 113 dB(A) 113 dB(A) |

| Operator Sound Pressure Level (ISO 6396:2008)* | 72 dB(A) 72 dB(A) |

| Machine Sound Power Level (ISO 6395:2008)* | 110 dB(A) 110 dB(A) |

| Note (1) | * Sound suppression equipped * Sound suppression equipped |

| Note (2) | The machine sound power level was measured according to ISO 6395:2008. The measurement was conducted at 70 percent of the maximum engine cooling fan speed. The machine sound power level was measured according to ISO 6395:2008. The measurement was conducted at 70 percent of the maximum engine cooling fan speed. |

| Note (3) | The operator sound pressure level was measured according to ISO 6396:2008. The measurement was conducted at 70 percent of the maximum engine cooling fan speed. The operator sound pressure level was measured according to ISO 6396:2008. The measurement was conducted at 70 percent of the maximum engine cooling fan speed. |

| Note (4) | Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment. Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment. |

| Steering System - Circuit | Pilot operated, load sensing Pilot operated, load sensing |

| Bore | 4.5 in 114.3 mm |

| Stroke | 22.7 in 576 mm |

| Steering System - Pump | Piston - Variable Displacement Piston - Variable Displacement |

| Maximum System Flow | 170 L/min @ 1,800 rpm (44.9 gal/min @ 1,800 rpm) 170 L/min @ 1,800 rpm (44.9 gal/min @ 1,800 rpm) |

| Steering Pressure Limited | 3481 psi 24000 kPa |

| Vehicle Articulation Angle | 86 ° 86 ° |

| Height to Top of Air Conditioning Condenser | 14.99 ft 4568 mm |

| Height - Cab Roof | 13.75 ft 4193 mm |

| Height - Top of Beacon | 15.63 ft 4765 mm |

| Height - Top of Exhaust Pipe | 14.56 ft 4439 mm |

| Height - Top of Hood | 10.87 ft 3312 mm |

| Ground Clearance - Bumper | 3.15 ft 960 mm |

| Centerline of Rear Axle to Edge of Counterweight - No Rear Radiator Guard | 9.38 ft 2860 mm |

| Centerline of Rear Axle to Edge of Counterweight - Including Rear Radiator Guard | 10.16 ft 3096 mm |

| Hitch to Centerline of Front Axle | 6.07 ft 1850 mm |

| Wheel Base | 12.14 ft 3700 mm |

| Length - With Blade on Ground - Straight Blade - Including Rear Radiator Guard | 28.59 ft 8715 mm |

| Ground Clearance | 2.11 ft 642 mm |

| Width - Over Wheels | 12.47 ft 3800 mm |

| Turning Radius - Inside of Wheels | 9.18 ft 2797 mm |

| Width – Moldboard Length | 14.16 ft 4311 mm |

| Width - Over End Bits | 14.75 ft 4502 mm |

| Height with Cutting Edge and Screen | 6.23 ft 1900 mm |

| Maximum Depth of Cut | 1.5 ft 461 mm |

| Maximum Lift above Ground | 4.19 ft 1277 mm |

| Capacity, Rated | 16.1 yd³ 12.3 m³ |

| Overall Machine Length (includes rear radiator guard, measured to cutting edge) | 28.59 ft 8715 mm |

| Width – Moldboard Length | 14.66 ft 4462 mm |

| Width - Over End Bits | 14.83 ft 4522 mm |

| Height with Cutting Edge and Screen | 6.63 ft 2022 mm |

| Maximum Depth of Cut | 2.03 ft 619 mm |

| Maximum Lift above Ground | 3.825 ft 1165 mm |

| Capacity, Rated | 20.9 yd³ 16 m³ |

| Overall Machine Length (includes rear radiator guard, measured to cutting edge) | 29.54 ft 9005 mm |

| Width – Moldboard Length | 14.25 ft 4331 mm |

| Width - Over End Bits | 14.41 ft 4398 mm |

| Height with Cutting Edge and Screen | 6.62 ft 2019 mm |

| Maximum Depth of Cut | 2.03 mm 619 mm |

| Maximum Lift above Ground | 3.79 ft 1156 mm |

| Capacity, Rated | 22.9 yd³ 17.5 m³ |

| Overall Machine Length (includes rear radiator guard, measured to cutting edge) | 30.7 ft 9357 mm |

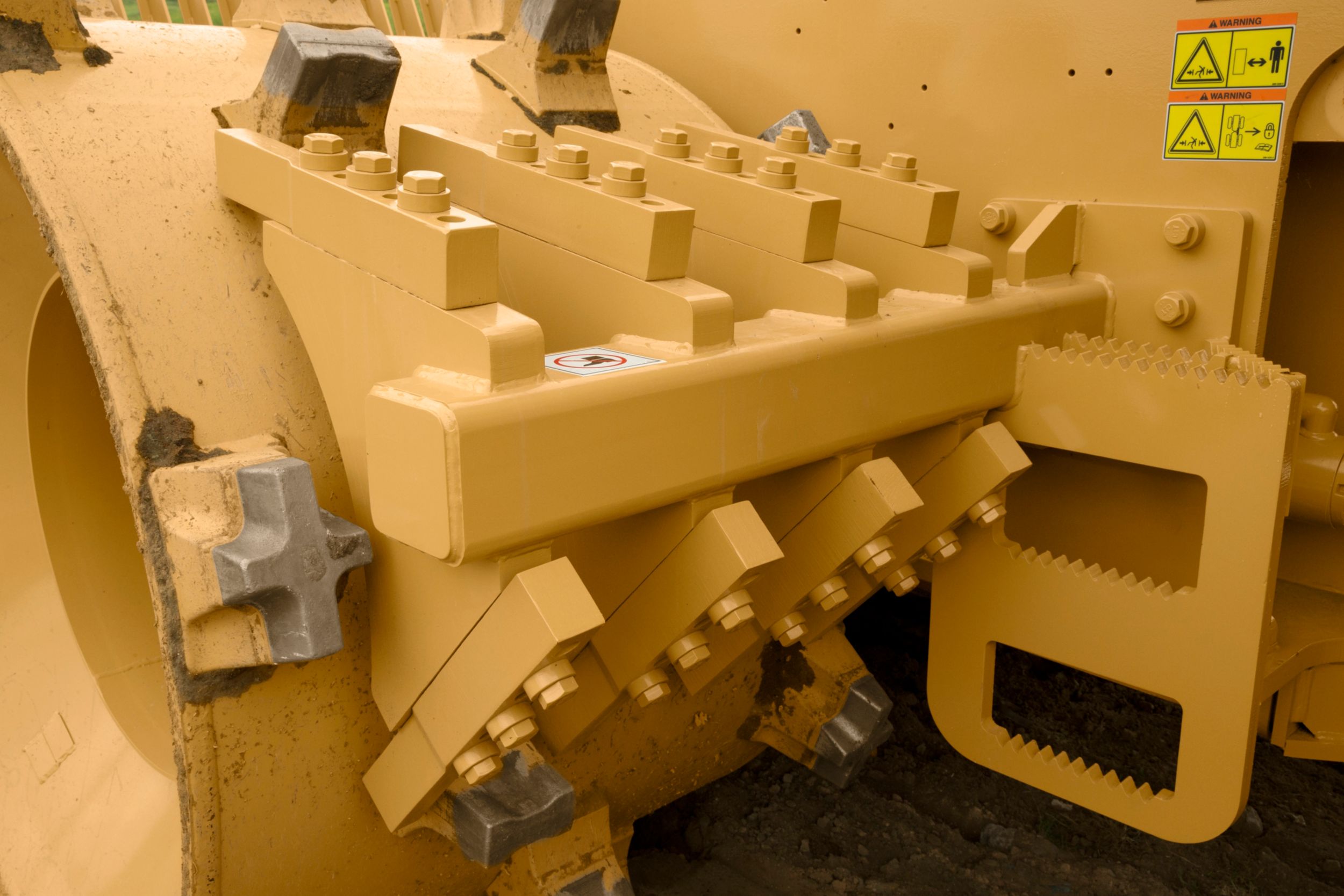

| Combination Tips (Weight Group) | 21125 lb 9582 kg |

| Plus Tips - Weight (Group) | 22002 lb 9980 kg |

| Paddle Tips - Weight (Group) | 20540 lb 9317 kg |

| Diamond Tips Weight (Group) | 23997 lb 10885 kg |

| Outside Diameter | 77.6 in 1971 mm |

| Outside Diameter - Diamond | 78.1 in 1983 mm |

| Drum Diameter | 63.4 in 1610 mm |

| Drum Width | 47.2 in 1200 mm |

| Feet Per Row | 6 6 |

| Feet Per Wheel | 30 30 |

| Replaceable | Weld On Weld On |

| Width Over Drums | 3800 mm 149.6 in |

| Tip Height | 179 mm 7 in |

| Tip Height - Diamond | 7.25 in 179 mm |

Advantages and Features

OPERATOR COMFORT AND CONTROL

- Flip-up armrest for easy ingress/egress.

- Keep your operators informed about machine conditions and operation with Vital Information Management System (VIMS™) 3G machine monitoring system.

- Enhanced visibility with standard rearview camera.

- Preferred temperature settings maintained with automatic climate control.

- Cat Premium Plus seat with standard features, including leather finish, forced air heating and cooling, two-way thigh adjustment, power lumbar and back bolster adjustment, and dynamic end dampening to provide total comfort throughout the workday.

- Low spectator sound levels and optional low sound packages.

TOP-TIER SERVICE AND SUPPORT

- Easy access in a controlled environment; electronics bay is located inside the cab.

- Focused on safety with ground level or platform access to most major components.

- Ground level: engine shutdown switch, lockable battery disconnect, and auxiliary jump start receptacle.

- Quick visual inspection and minimized fluid contamination with sight gauges for coolant, transmission, and hydraulic oil.

- Electronic air inlet restriction indicator.

- Designed for ease of service and inspection.

– Hydraulic oil cooler, fuel cooler, and roof-mounted condenser

– Centralized grease points - Operators and technicians can resolve any problems before failure using VIMS.

- Guarding around the axles mitigates risk of damaged components.

EFFICIENCY AND PRODUCTIVITY

- Improved performance, long life, low emissions.

- High productivity and fuel efficient.

- Two engine options available that meet U.S. EPA Tier 4 Final and EU Stage V emission standards or emitting equivalent to U.S. EPA Tier 3 and EU Stage IIIA.

- For the Tier 4 Final, EU Stage V option, the Cat Clean Emissions Module contains a diesel oxidation catalyst, diesel particulate filter, and Cat Regeneration System, utilizing selective catalytic reduction (SCR) technology.

- Regeneration is completely automatic and does not interrupt the machine’s work cycle.

- Experience maximum responsiveness and control with Steering and Transmission Integrated Control (STIC™) system.

- Conserve more fuel with the automatic engine and electrical system shutdown.

- Achieve greater momentum on grades and fuel savings by carrying that momentum through the shift points advanced productivity electronic control system (APECS) transmission controls.

- Operators experience less fatigue with throttle lock to maintain engine speed.

- Equipped with Cat torque converter with lock-up clutch which eliminates torque converter (TC) losses while lowering system heat and transfers more power to the ground.

- Torque converter with lock-up clutch eliminates torque converter losses while lowering system heat. Improves travel speeds and increases fuel efficiency.

- Lock-up torque converter transfers more power to the ground and optimizes fuel efficiency in all applications.

PRODUCTIVITY WITH TECHNOLOGY

- Compact technology combines advanced compaction measurement, in-cab guidance, and reporting capabilities to help you consistently meet compaction targets fast, uniformly, and in fewer passes – saving on fuel and the cost of unnecessary rework.

- Link technology (standard) provides access to machine location, hours, fuel consumption, idle time, events, and diagnostic codes through the online VisionLink® interface.

- Improved productivity with optional Cat Compact with Elevation Mapping.

LONG-TERM VALUE AND DURABILITY

Working in the toughest application, the purpose-built 826 Landfill Compactor has specialized waste guarding to protect key components and systems from damage, debris, chemicals, premature wear, or wrapping of the material around components. This additional guarding includes:

- Engine and Powertrain Guards – Hydraulically actuated guards help prevent trash buildup and shield components.

- Front Frame Guards – Front frame guards prevent trash buildup inside the frame. This guard further protects components and hydraulic lines.

- Axle Wrapping and Seal Guarding – The guarding prevents material from wrapping and binding around the axles, as well as assists in ease of cleaning.

- Major System Guarding and Sight Gauges – Transmission oil tube is guarded to resist damage from debris. The sight gauge for the transmission is visible from ground level. The fuel tank is positioned away from the debris in the front frame and is easily accessed.

- Air Inlet Screen – The vertically corrugated, fine-mesh air inlet screen helps reduce trash from entering the radiator area and allows for debris to fall off.

- Striker Bars and Optional Cleaner Fingers – Striker bars are located in front of and behind the rear wheels and behind the front wheels. Striker bars help to keep wheels free of debris to assist the wheel step tips in maintaining good compaction. In cohesive material or severe packing conditions, optional cleaner fingers are available to further assist in keeping the wheel step tips clean.

- Extended Roof – An oversized roof extends past the cab doors and windows to minimize debris buildup.

- Under Hood Ventilation System – Creates a neutral pressure environment to prevent trash ingestion from hood openings while providing fresh air to the alternator, electronics, and turbo.

WHEEL TIPS BUILT TO PERFORM

- Designed specifically to complement Cat machines.

- Improves machine performance through longer wear life and maintaining traction.

- Four wheel and tip configurations are available to meet your particular application:

- Paddle Tip – High performance and less fuel burn with more traction and less weight.

- Plus Tip – Traditional design for increased side slope stability.

- Combination Tip – Both paddle and plus tips provide the best compromise of performance and fuel economy with side slope stability.

- Diamond Tip – Longest life tip on the market with reputation of reliability that is world class in the waste tip industry.

Standard Equipment

-

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

POWERTRAIN

- Single Clutch Speed Shifting (SCSS)

- Electronic Clutch Pressure Control (ECPC)

- Air-to-air aftercooler

- Brakes, full hydraulic, enclosed, wet multiple disc service brakes

- Cat Clean Emission Module (U.S. EPA Tier 4 Final/ EU Stage V only)

- Muffler (under hood) (U.S. EPA Tier 3/EU Stage IIIA equivalent)

- Electro-hydraulic parking brake

- Engine, Cat C15 configured for two emissions options: Tier 4 Final/Stage V, or emitting equivalent to Tier 3/Stage IIIA

- Fuel priming pump (electric)

- Fuel-to-air cooler

- Ground level engine shutdown

- Heat shield, turbo and exhaust manifold

- Hydraulically driven demand fan

- Integrated braking system

- Radiator, Aluminum Modular (AMR)

- Separated cooling system

- Starting aid (ether)

- Throttle lock

- Torque converter with Lock Up Clutch (LUC)

- Eco Mode

- Transmission, planetary, with 2F/2R speed range control

- Under hood ventilation system

-

ELECTRICAL

- Alarm, back-up

- Alternator, 150 amp

- Batteries, maintenance-free (4 - 1,000 CCA)

- Electrical system, 24V

- Light, warning unswitched (LED strobe)

- Lighting system, halogen (front and rear)

- Lighting, access stairway

- Lighting, underhood

- Starter, electric (heavy duty)

- Ground level lockable master disconnect switch

- Auxiliary jump start receptacle

-

OPERATOR ENVIRONMENT

- Camera, rear vision

- Air conditioner with roof-mounted condenser

- Cab, sound-suppressed pressurized

- Internal four-post rollover protective structure (ROPS/FOPS)

- Radio ready for entertainment: – Antenna – Speakers – Converter (12V, 10-15 amp)

- 12V power port for mobile phone or laptop connection

- Radio, CB ready

- Coat and hard hat hooks

- Fingertip shifting controls

- Flip-up armrest

- Heater and defroster

- Implement hydraulic lockout

- Glass (window) - rubber mounted glass

- Light, (dome) cab

- Lunch box and beverage holders

- Instrumentation, gauges: – Diesel exhaust fluid (DEF) level (U.S. EPA Tier 4 Final/ EU Stage V) – Engine coolant temperature – Fuel level – Hydraulic oil temperature – Speedometer/tachometer – Torque converter temperature

- Instrumentation, warning indicators: – Action alert system, three categories – Brake oil pressure – Electrical system, low voltage – Engine failure malfunction alert and action lamp – Parking brake status

- Mirror, internal (panoramic)

- Mirrors, heated, rearview (externally mounted)

- Premium plus seat containing forced air heating and cooling, 2-way thigh adjustment, power lumbar and back bolster adjustment, ride stiffness adjustment, dynamic end dampening, and leather finish

- Seat belt with minder, retractable, 76 mm (3 in) wide

- Steering and Transmission Integrated Control (STIC™) system with lockout

- Sun visor, front

- Tinted glass

- Transmission gear (indicator)

- Vital Information Management System (VIMS™): – Graphical information display – External data port – Customizable operator profiles

- Wet-arm wipers/washers (front and rear)

- Intermittent wipers (front and rear)

- Precleaner, cab powered

- Horn group (trumpet)

-

GUARDS

- Guards, axle (front and rear)

- Guard, cab window

- Guard, driveshaft

- Guards, crankcase and powertrain, hydraulically powered

- Guard, differential (front and rear)

-

FLUIDS

- Antifreeze, premixed 50% concentration extended life (–34° C/–29° F)

-

OTHER STANDARD EQUIPMENT

- Demand fan/swing out (hydraulic reversible)

- Doors, service access (locking)

- Ecology drains for engine, radiator, transmission, hydraulic tank

- Emergency platform exit

- Engine, crankcase, 500 hour interval with CJ-4 oil

- Engine idle management features: – Auto idle kickdown – Delayed engine shutdown – Engine idle shutdown

- Fire suppression ready

- Fuel tank, 782 L (207 gal)

- Hitch, drawbar with pin

- Hoses, Cat XT™

- Hydraulic, engine, and transmission oil coolers

- Total hydraulic filtration system

- Oil sampling valves

- Oil change system, high speed

- Steering, load sensing

- Stairway, left and right rear access

- Vandalism protection caplocks

- Venturi stack

- Fold-down exhaust stack for shipping

-

TECHNOLOGY PRODUCTS

- Product Link™ – Cellular, Satellite

-

SPECIAL ARRANGEMENTS

- Engine: – Sound suppression

- Engine precleaners - single stage

-

BLADES

- Dozer arrangement (no blade)

-

WHEELS AND CLEANER BARS

- Striker bars

- Wheels and tips: wheel arrangements – 7" combination tips

Optional Equipment

-

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

OPERATOR ENVIRONMENT

- Radio, AM/FM/Aux/USB/Bluetooth®

- Cat Compact SBAS Mapping (available through SITECH only)

- Cat Compact RTK Mapping (available through SITECH only)

-

GUARDS

- Guard – rear fan and grill

-

POWERTRAIN

- Heater, engine coolant, 120V

- Heater, engine coolant, 240V

-

SPECIAL ARRANGEMENTS

- Engine precleaners – dual stage

-

MISCELLANEOUS

- Plate – year of manufacture (Tier 3/Stage IIIA equivalent only)

-

WHEELS AND CLEANER BARS

- Striker bars with cleaner fingers

-

OTHER STANDARD EQUIPMENT

- Stairway, swingout (LH & RH)

826 Landfill Compactor - Key Features (Global)

826 Landfill Compactor - Key Features (Global)

826 (11A) Landfill Compactor - Technical Specifications (Global)

826 (11A) Landfill Compactor - Technical Specifications (Global)

826 Landfill Compactor - Product Brochure (Global)

826 Landfill Compactor - Product Brochure (Global)