Technicial Specifications

| Net Power - ISO 9249 | 212 HP 157.8 kW |

| Engine Model | Cat C7.1 Cat C7.1 |

| Engine Power - ISO 14396 | 213 HP 159 kW |

| Bore | 4 in 105 mm |

| Stroke | 5 in 135 mm |

| Displacement | 428 in³ 7.01 l |

| Operating Weight | 61700 lb 28000 kg |

| Maximum Digging Depth | 23.1 ft 7260 mm |

| Boom | Reach 6.15 m (20.2 ft) Reach 6.15 m (20.2 ft) |

| Stick | Reach 3.2 m (10.5 ft) Reach 3.2 m (10.5 ft) |

| Bucket | HD 1.60 m³ (2.09 yd³) HD 1.60 m³ (2.09 yd³) |

| Maximum Reach at Ground Level | 35.1 ft 10690 mm |

| Maximum Cutting Height | 32.9 ft 9980 mm |

| Maximum Loading Height | 22.8 ft 6930 mm |

| Minimum Loading Height | 7.5 ft 2280 mm |

| Maximum Depth Cut for 2440 mm (8 ft) Level Bottom | 23.3 ft 7100 mm |

| Maximum Vertical Wall Digging Depth | 19 ft 5800 mm |

| Bucket Digging Force - ISO | 40200 lbf 179 kN |

| Stick Digging Force - ISO | 28300 lbf 126 kN |

| Main System - Maximum Flow | 560 l/min (148 gal/min) 560 l/min (148 gal/min) |

| Maximum Pressure - Equipment | 5075 psi 35000 kPa |

| Maximum Pressure - Travel | 5075 psi 35000 kPa |

| Maximum Pressure - Swing | 4120 psi 28400 kPa |

| Swing Speed | 11.5 r/min 11.5 r/min |

| Maximum Swing Torque | 77370 ft·lbf 105 kN·m |

| Fuel Tank Capacity | 125.2 gal (US) 474 l |

| Cooling System | 6.6 gal (US) 25 l |

| Engine Oil | 6.6 gal (US) 25 l |

| Swing Drive - Each | 2.6 gal (US) 10 l |

| Final Drive - Each | 1.5 gal (US) 5.5 l |

| Hydraulic System - Including Tank | 81.9 gal (US) 310 l |

| Hydraulic Tank | 38.8 gal (US) 147 l |

| Boom | Reach 6.15 m (20.2 ft) Reach 6.15 m (20.2 ft) |

| Stick | Reach 3.2 m (10.5 ft) Reach 3.2 m (10.5 ft) |

| Bucket | HD 1.60 m³ (2.09 yd³) HD 1.60 m³ (2.09 yd³) |

| Shipping Height - Top of Cab | 10 ft 3050 mm |

| Handrail Height | 10 ft 3050 mm |

| Shipping Length | 34.2 ft 10420 mm |

| Tail Swing Radius | 10.3 ft 3130 mm |

| Counterweight Clearance | 3.7 ft 1110 mm |

| Ground Clearance | 1.6 ft 490 mm |

| Track Length | 14.4 ft 4350 mm |

| Length to Center of Rollers | 11.4 ft 3490 mm |

| Track Gauge | 7.8 ft 2390 mm |

| Transport Width | 10.5 ft 3190 mm |

Advantages and Features

LATEST FEATURES

- Optional integrated vehicle health management system alerts the operator with service guidance and parts needed to enhance uptime.

- Enhance visibility to make service work easier and safer with optional inspection lighting.

- Make the jobsite safer with an optional swing alarm.

Build Number: 07E

DO MORE WITH LESS FUEL

- Use up to 12 percent less fuel than the 330D2 Excavator in similar applications.

- Increase operating efficiency up to 45 percent with standard Cat technologies that lower operator fatigue and your operating costs, including fuel consumption and daily maintenance.

- The C7.1 engine can run on biodiesel up to B20 and meets U.S. EPA Tier 3/EU Stage IIIA/China Nonroad Stage III/Brazil Mar-1 equivalent emission standards.

- Match the excavator to the job with power modes; let Smart mode automatically match engine and hydraulic power to digging conditions.

- Auxiliary hydraulic options give you the versatility to use a wide range of Cat attachments.

- Don’t let the temperature stop you from working. The excavator has a standard high-ambient temperature capability of 52° C (125° F) and cold start capability of –18° C (0° F). An optional –32° C (–25° F) cold start package is available.

LONG TERM VALUE AND DURABILITY

- Work up to 3000 m (9,840 ft) above sea level without de-rating.

- Don’t let the temperature stop you from working. The excavator has a standard high-ambient temperature capability of 52° C (125° F) and cold start capability of –18° C (0° F). An optional – 32° C (–25° F) cold start package is available.

- Auto warm up speeds up hydraulic oil warming in cold temperatures and helps prolong the life of components.

- Two levels of fuel filtration protect the engine from dirty diesel fuel.

- Grease sealed between track pins and bushings reduces travel noise and prevents debris from entering to increase undercarriage life.

- The track guiding guard helps keep the excavator track aligned when traveling and working on slopes.

- The sloped track frame prevents mud and debris accumulation, helping reduce risk of track damage.

WORK COMFORTABLY IN NEW CAB

- The cab has a wide seat that adjusts for operators of all sizes.

- Control the excavator comfortably with easy-to-reach controls all located in front of you.

- Standard automatic climate control keeps you at the right temperature all shift long.

- Advanced viscous mounts reduce cab vibration by up to 50 percent over previous excavator models.

- Stow your gear with plenty of in-cab storage beneath and behind the seat, overhead, and in the consoles. A cup holder, document holder, bottle holder, and coat hook are also provided.

- Use the standard radio’s USB ports and Bluetooth® technology to connect to personal devices.

DESIGNED FOR OPERATORS

- Start the engine with a push button; use a Bluetooth key fob,or the unique Operator ID function.

- Program your power mode and joystick preferences using Operator ID; the excavator will remember what you set each time you go to work.

- Navigate quickly on the standard high-resolution 203 mm (8 in) touchscreen monitor or with the aid of the jog dial control.

- Protect your hammer tool from overheating and rapid wear. Auto hammer stop warns you after 15 seconds of continuous firing and then automatically shuts it off after 30 seconds - all to extend the tool’s service life.

- Not sure how a function works or how to maintain the excavator? Always have the operator’s manual at your fingertips in the touchscreen monitor.

- The Cat PL161 Attachment Locator is a Bluetooth device that makes finding your attachments and other gear quick and easy. The Cat App on your phone will locate the device automatically.

- Find the tool you need – even if it’s hidden beneath overgrowth or debris. The available Bluetooth reader can search for any work tool equipped with Cat asset tracking devices up to a range of 60 m (200 ft).

LOWER MAINTENANCE COSTS

- Expect up to 25 percent less maintenance cost than the 330D2 (savings calculated over 12,000 machine hours).

- Do all daily maintenance at ground level.

- Check engine oil level quickly and safely with the new ground-level engine oil dipstick; fill and check engine oil on top of the machine with a conveniently located second dipstick.

- Track your excavator’s filter life and maintenance intervals via the in-cab monitor.

- Expect the new air intake filter with pre-cleaner to last up to 1,000 hours – a 100 percent increase over the previous filter.

- The new hydraulic oil filter provides improved filtration performance, anti-drain valves to keep oil clean when the filter is replaced, and longer life with a 3,000-hour replacement interval – 50 percent longer than previous filter designs.

- High-efficiency cooling fans run only when needed; you can program intervals so they automatically reverse to keep cores clean without interrupting your work.

- Boost productivity with proactive service reminders. Our new integrated vehicle health management system alerts the operator with step-by-step service guidance, along with parts needed, so you don't experience any unnecessary downtime.

- S·O·SSM ports simplify maintenance and allow for quick, easy extraction of fluid samples for analysis.

SAFELY HOME EVERY DAY

- Access 100 percent of daily maintenance points from ground level – no need for you to climb on top of the excavator.

- Keep your excavator secure with Operator ID. Use your PIN code on the monitor to enable the pushbutton starting feature.

- The standard ROPS cab meets ISO 12117-2:2008 requirements.

- Enjoy great visibility into the trench, in each swing direction, and behind you with the help of smaller cab pillars, larger windows, and a flat engine hood design. A rearview camera is standard, and a right-side-view camera is available.

- New right service platform design provides easy, safe, and quick access to upper service platform; the service platform steps use anti-skid punch plate to prevent slipping.

- The standard hydraulic lockout lever isolates all hydraulic and travel functions in the lowered position.

- Ground-level shut-off switch stops all fuel to the engine when activated and shuts down the machine.

- Enhance jobsite safety. Add a swing alarm to alert people when you're rotating from trench to stockpile and back again.

- Make service work easier and safer with optional inspection lighting. With the flip of a switch, lights will illuminate the engine, pump, battery, and radiator compartments to enhance visibility.

Standard Equipment

-

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

CAB

- Rollover protective structure (ROPS)

- Mechanically adjustable seat

- High-resolution 203 mm (8 in) LCD touchscreen monitor

-

CAT TECHNOLOGY

- Cat Product Link™

- Auto hammer stop

-

ELECTRICAL SYSTEM

- Two 1,000 CCA maintenance free batteries

- Programmable time-delay LED working lights

- LED chassis light, left-hand boom light

-

ENGINE

- Cat C7.1 single turbo diesel engine

- Two selectable power modes

- Auto engine speed control

- Auto engine idle shutdown

- 52°C (125°F) high-ambient cooling capacity

- -18°C (0°F) cold start capability

- Double element air filter with integrated precleaner

- Reversing electric cooling fans

- Biodiesel capability up to B20

-

HYDRAULIC SYSTEM

- Boom and stick regeneration circuits

- Auto hydraulic warm up

- Auto two-speed travel

- Boom and stick drift reduction valve

-

SAFETY AND SECURITY

- Rearview camera

- Ground-level engine shutoff switch

- Right-hand handrail and hand hold

- Signaling/warning horn

-

SERVICE AND MAINTENANCE

- Sampling ports for Scheduled Oil Sampling (S·O·S)

- Ground-level and platform-level engine oil dipsticks

-

UNDERCARRIAGE AND STRUCTURES

- Tie-down points on base frame

Optional Equipment

-

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

BOOMS AND STICKS

- 6.15 m (20'2") Reach boom

- 5.55 m (18'2") Mass boom

- 3.2 m (10'6") Reach stick

- 2.65 m (8'8") Reach stick

- 2.5 m (8'2") Mass stick

-

ELECTRICAL SYSTEM

- Cab lights, right-hand boom light

-

ENGINE

- -32°C (-25°F) cold start capability

-

HYDRAULIC SYSTEM

- Boom and stick lowering check valves

- Hammer return filter circuit

- Tool Control (two pump, one/two way high-pressure flow)

- Basic Tool Control (one pump, one way high-pressure flow)

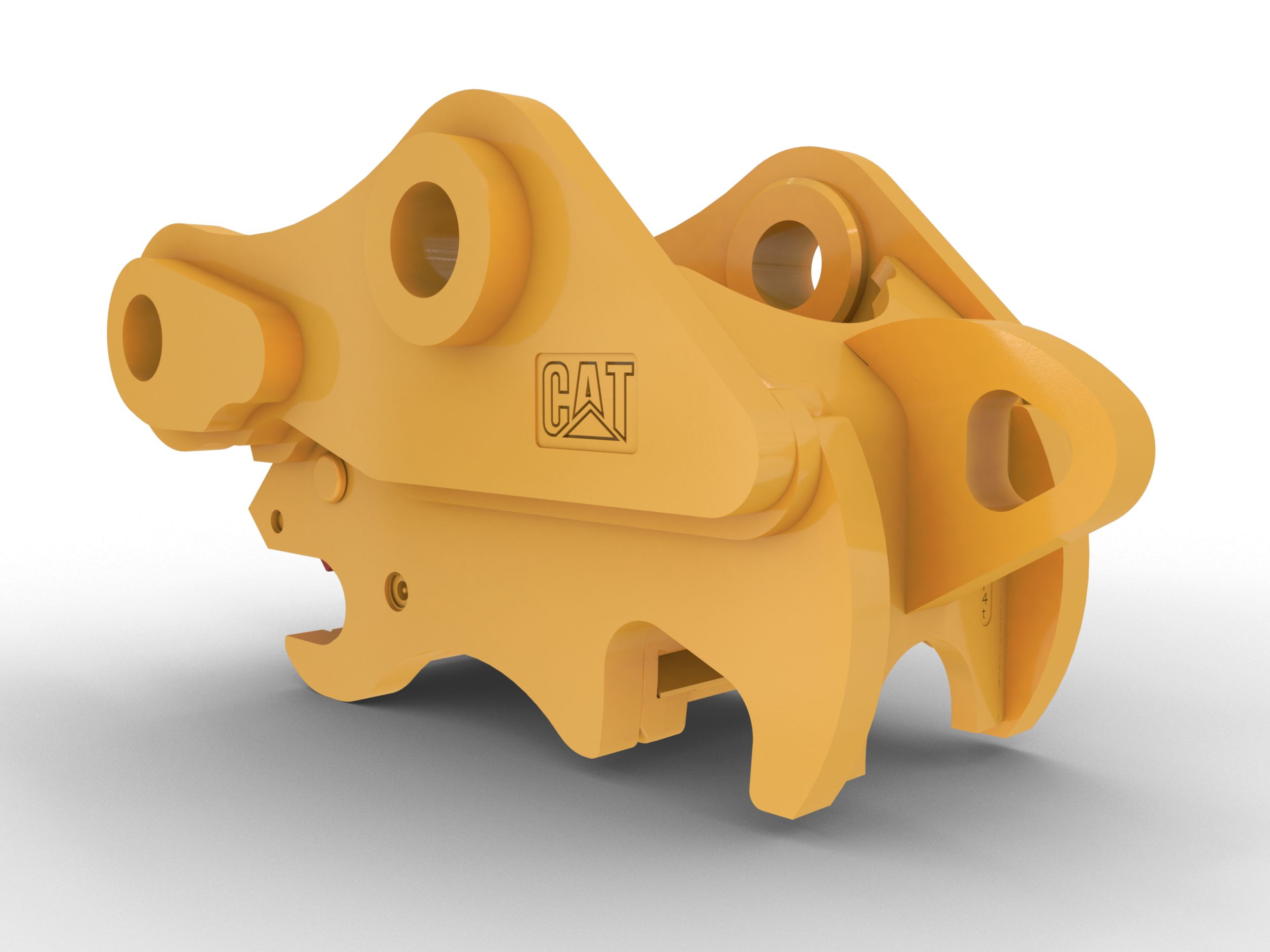

- Quick coupler circuit

-

SAFETY AND SECURITY

- Right-hand-sideview camera (Standard for Australia, New Zealand, Kingdom of Saudi Arabia)

- Swing alarm

- Inspection lighting

-

SERVICE AND MAINTENANCE

- Electric refueling pump with auto shutoff

- Integrated vehicle health management system

-

UNDERCARRIAGE AND STRUCTURES

- Standard undercarriage

- Long undercarriage

- 600 mm (24") triple grouser shoes

- 600 mm (24") HD triple grouser shoes

- 700 mm (28") triple grouser shoes

- 700 mm (28") HD triple grouser shoes

- 800 mm (31") triple grouser shoes

- 600 mm (24") triple grouser shoes

- 700 mm (28") triple grouser shoes

- 800 mm (31") triple grouser shoes

- 5800 kg (12,790 lb) counterweight

- 6700 kg (14,770 lb) counterweight

330 GC Product Brochure

330 GC Product Brochure

330 GC Technical Specifications (Afr-ME, AP, Eurasia, S Am)

330 GC Technical Specifications (Afr-ME, AP, CIS, S Am)

330 GC Technical Specifications (Aus-NZ)

330 GC Technical Specifications (China)

330 GC Technical Specifications (India)

330 GC Technical Specifications (India)