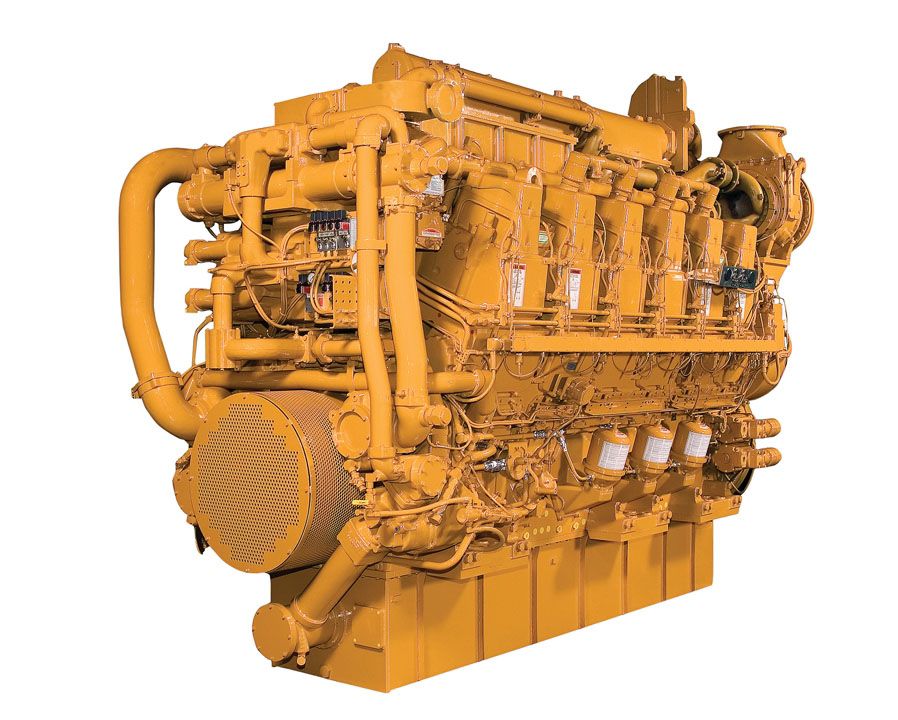

Technicial Specifications

| Power Range | 2320-2722 bhp (1730-2030 bkW) 2320-2722 bhp (1730-2030 bkW) |

| Speed Range | 900-1000 rpm 900-1000 rpm |

| Emissions | IMO II IMO II |

| Aspiration | TA TA |

| Bore | 11 in 280 mm |

| Stroke | 11.8 in 300 mm |

| Displacement | 6773 in³ 111 l |

| Rotation from Flywheel End | Counterclockwise or clockwise Counterclockwise or clockwise |

| Configuration | In-line 6, 4-Stroke-Cycle Diesel In-line 6, 4-Stroke-Cycle Diesel |

| Dry Weight | 34496 lb 15680 kg |

| Length | 158 in 4013 mm |

| Width | 71 in 1803 mm |

| Height | 108 in 2743 mm |

Advantages and Features

A3 ECU

• CAN J1939 data link • Waterproof connectors • Maintenance-free • Backup ECU for redundant governingElectronic Advantages:

• Load feedback • Programmable droop • Adjustable gain • Adjustable fuel/air ratio control • Histograms of engine operation • Cat Messenger display presents diagnostics and other engine parametersData Advantages through J1939 Link:

• Engine speed • Boost pressure • Throttle position • Fuel consumption rate • Inlet manifold temperature • Diagnostic codes and events • Configuration • Desired engine speed • Battery voltage • Engine load • Lifetime totals — engine hours, fuel burned, idle fuel, idle hours • Trip totals — average fuel rate, idle fuel, idle hours, engine hours, fuel burned, trip resetCustomer Interface Panel

• Interfaces with standard Cat® Marine Monitoring System (PLC in Price List) • Provides visual indication of ECU functionality • Accepts 4 — 20 mA or PWM remote throttle speed input • Marine alarm and protectionElectronic Unit Injectors

• “Drop-in” installation • No threaded fuel connections • High pressure inside injector only • Does not require double wall fuel lines or leak collection device • Injector synchronization not requiredStandard Equipment

-

General

- LH or RH service connections

-

Air Inlet System

- Aftercooler, fresh water, corrosion resistant coated

- Crankcase breathers, top-mounted

- Single turbocharger, rear-mounted, engine oil lubricated

- Air inlet adapter - Straight / 90 degree / 35 degree

-

Control System

- Dual Caterpillar ADEM A4 Electronic Engine Control Modules

- Rigid Wiring Harness

- Aftercooler / oil cooler and jacket water pumps (gear driven)

-

Cooling System

- Engine coolant water drains

- Single Circuit / Separate Circuit Aftercooler

- Dry, gas tight, exhaust manifold

-

Exhaust System

- Dry, gas tight, exhaust manifold

- Turbo speed sensors - overspeed protection

- Exhaust manifold shielding, soft

-

Fuel System

- Fuel transfer pump, gear driven

- Electronically Controlled Unit Injectors

-

Instrumentation

- CAT Alarm & Protection System

-

Lube System

- Oil pump, gear driven

-

Lube Systems

- 2 element oil cooler, engine mounted

- Duplex centrifugal oil filter-engine mounted

- Wet sump

- Prelube pump - air / electric

-

Protection System

- Crankcase explosion relief valves

-

Protection Ssystem

- Mounted oil mist detector

Optional Equipment

-

Fuel System

- Fuel priming pump

- Duplex fuel filters

- SOLAS shielding

-

Lube System

- Front and rear oil pan drains

- SOLAS shielding

-

Protection System

- Cylinder pressure relief valves