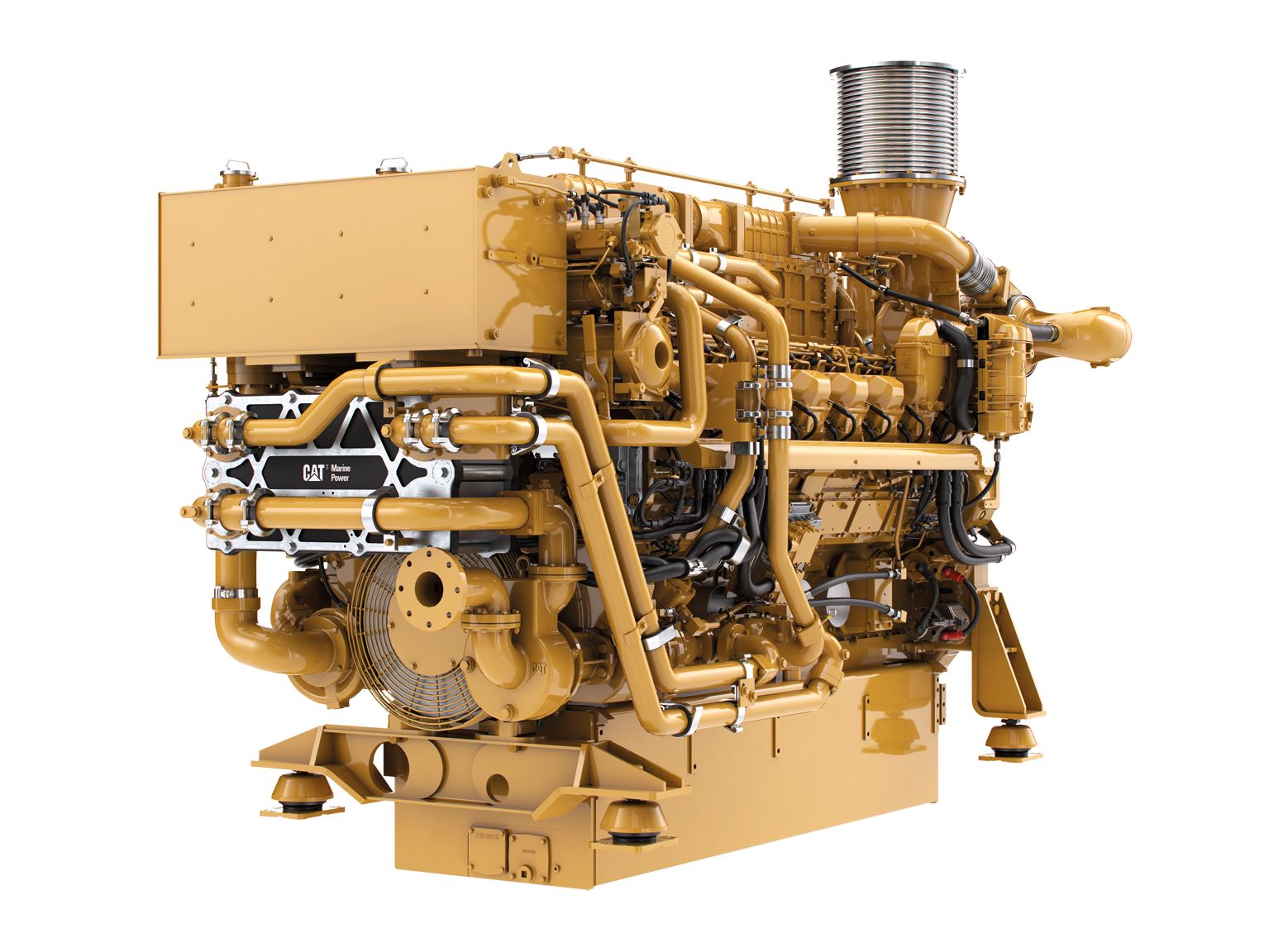

Technicial Specifications

| Power Range | 2501-3386 bhp (1865-2525 bkW) 2501-3386 bhp (1865-2525 bkW) |

| Speed Range | 1600-1800 rpm 1600-1800 rpm |

| Emissions | U.S. EPA Tier 4 Final, IMO III U.S. EPA Tier 4 Final, IMO III |

| Aspiration | TTA TTA |

| Bore | 6.69 in 170 mm |

| Stroke | 8.46 in 215 mm |

| Displacement | 4765 in³ 78 l |

| Rotation from Flywheel End | Counterclockwise Counterclockwise |

| Configuration | Vee 16, 4-Stroke-Cycle Diesel Vee 16, 4-Stroke-Cycle Diesel |

| Width | 89.9 in 2284 mm |

| Length | 125.7 in 3192 mm |

| Height | 87.6 in 2225 mm |

| Dry Weight | 21164 lb 9600 kg |

Advantages and Features

Emissions

Utilizes SCR Technology to enable U.S. EPA Tier 4 Final emission regulations compliance while lowering operational costs, IMO III emissions compliantUtilizes closed loop air assisted DEF dosing control strategy

Highest efficiency mixing and control to lower operational costs, extends emissions useful life, ensures compliance, flexibility regarding urea qualityAdvanced Engine Combustion Design

Advanced engine combustion design process utilizing optimum configurations and cylinder geometry for maximum engine efficiencyEnhanced control of fuel injection

Enhanced control of fuel injection optimized through crank timing and thelatest A5 ECM technologyEnhanced Fuel Delivery

Optimal fuel injector nozzle geometry and electronic injection control for improved fuel deliveryIncreased Durability and Higher Engine Duty Cycle Capability

Strengthened cylinder heads and valves for increased durability and peak cylinder pressure capability resulting in higher engine duty cycle capabilityCaterpillar Warranty

Industry-leading warranty coverage for factory packaged componentsGlobal Dealer Network

No matter where or when, our extensive global dealer network is ready to provide supportStandard Equipment

-

Air Inlet System

- Corrosion-resistant aftercooler core

-

Control System

- Dual A5 engine control modules with electronic unit injection and low pressure fuel system

-

Cooling System

- Auxiliary fresh water pump

- Gear Driven, centrifugal jacket water pump with 40% more capacity

-

Exhaust System

- Dual turbochargers with water-cooled bearings and heat shields

-

Fuel System

- Duplex Fuel and Oil Filtration

-

General

- Vibration damper and guard

- Meets SOLAS regulations