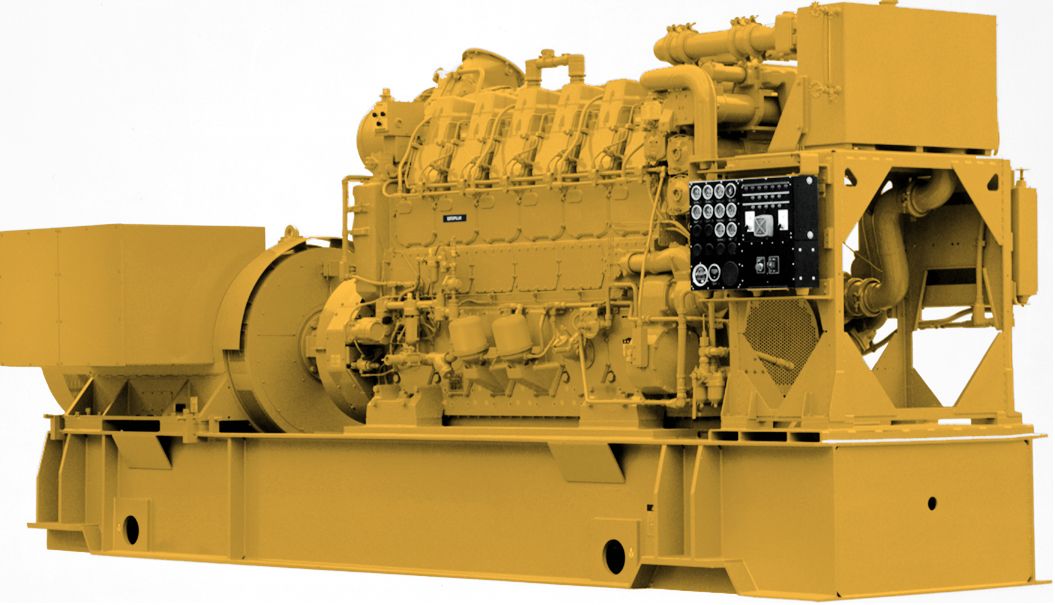

Technicial Specifications

| Power Range | 1720 - 1820 ekW 1720 - 1820 ekW |

| Frequency | 50 / 60 Hz 50 / 60 Hz |

| Emissions/Fuel Strategy | U.S. EPA Tier 2, IMO II U.S. EPA Tier 2, IMO II |

| Aspiration | Turbocharged - Aftercooled Turbocharged - Aftercooled |

| Bore | 11 in 280 mm |

| Stroke | 11.8 in 300 mm |

| Displacement | 6773 in³ 111 l |

| Governor Type | Electronic Electronic |

| Fuel System | EUI EUI |

| Compression Ratio 50 Hz | 13.1 13.1 |

| Compression Ratio 60 Hz | 13:1 13:1 |

| Engine Model | In-line 6, 4-Stroke-Cycle Diesel In-line 6, 4-Stroke-Cycle Diesel |

| Length | 280.3 in 7120 mm |

| Width | 77.2 in 1961 mm |

| Height | 154.9 in 3934 mm |

| Weight - Estimated | 18000 lb 8165 kg |

Advantages and Features

A3 ECU

Advantages

CAN J1939 data link Waterproof connectors, Maintenance-free, Backup ECU for redundant governing

Electronic Advantages

Load feedback, Programmable droop, Adjustable gain, Adjustable fuel/air ratio control, Histograms of engine operation, Cat Messenger display presents diagnostics and other engine parameters

Data Advantages through J1939 Link

Engine speed, Boost pressure, Throttle position, Fuel consumption rate, Inlet manifold temperature, Diagnostic codes and events, Configuration, Desired engine speed, Battery voltage, Engine load, Lifetime totals — engine hours, fuel burned, idle fuel, idle hours, Trip totals — average fuel rate, idle fuel, idle hours, engine hours, fuel burned, trip reset

Customer Interface Panel

Advantages

Interfaces with standard Cat® Marine Monitoring System (PLC in Price List), Provides visual indication of ECU functionality, Accepts 4 — 20 mA or PWM remote throttle speed input, Marine alarm and protection

Electronic Unit Injectors

Advantages

“Drop-in” installation, No threaded fuel connections, High pressure inside injector only, Does not require double wall fuel lines or leak collection device, Injector synchronization not required

Standard Equipment

-

General

- LH or RH service connections

-

Air Inlet System

- Aftercooler — fresh water, corrosion resistant coated

- Crankcase breathers, top-mounted

- Single turbocharger, rear-mounted, engine oil lubricated

-

Exhaust System

- Air inlet adapter - Straight / 90 degree / 35 degree

- Dry, gas tight, exhaust manifold

- Turbo speed sensors - overspeed protection

- Exhaust manifold shielding, soft

-

Control System

- Dual Caterpillar ADEM A4 Electronic Engine Control Modules

- Rigid Wiring Harness

-

Cooling System

- Aftercooler/oil cooler and jacket water pumps (gear driven)

- Engine coolant water drains

- Single Circuit / Separate Circuit Aftercooler

-

Fuel System

- Fuel transfer pump, gear driven

- Electronically Controlled Unit Injectors

-

Instrumentation

- CAT Alarm & Protection System

-

Lube System

- Oil pump, gear driven

- 2 element oil cooler, engine mounted

- Duplex centrifugal oil filter - engine mounted

- Wet sump

- Prelube pump - air / electric

-

Protection System

- Mounted oil mist detector

- Crankcase explosion relief valves

Optional Equipment

-

Fuel System

- Fuel priming pump

- Duplex fuel filters

- SOLAS shielding

-

Lube System

- Front and rear oil pan drains

- SOLAS shielding

-

Protection System

- Cylinder pressure relief valves