Technicial Specifications

| Continuous Rating | 2541/ 2500 ekW @ 1.0pf 2541/ 2500 ekW @ 1.0pf |

| Fuel Type | Natural Gas & Propane Natural Gas & Propane |

| Maximum Electrical Efficiency | 46.0% 46.0% |

| Frequency | 50 / 60 Hz 50 / 60 Hz |

| RPM | 1500 1500 |

| Frequency | 50/60 Hz 50/60 Hz |

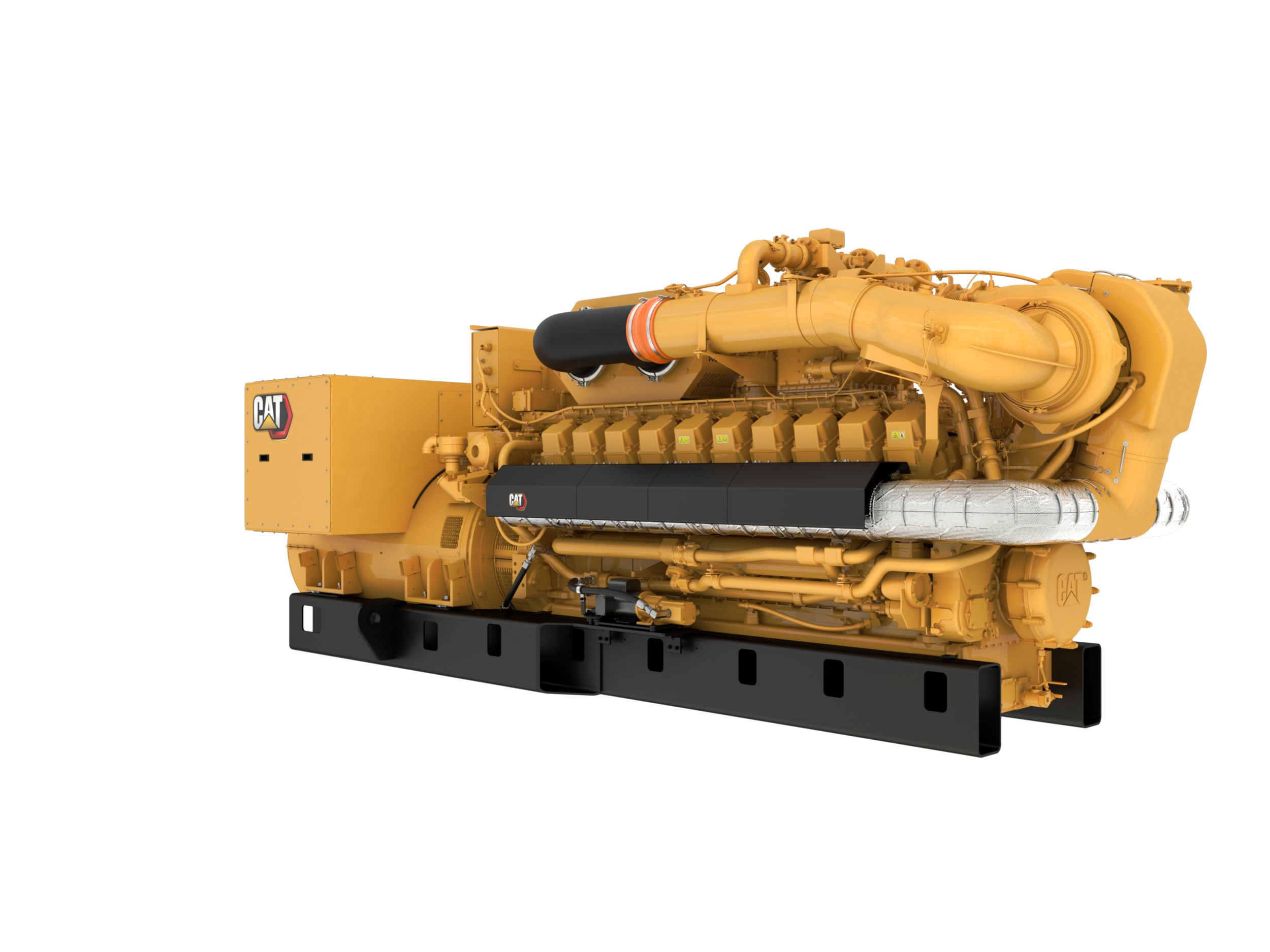

| Engine Model | G3520K G3520K |

| Displacement | 5956 in³ 97.6 l |

| Aspiration | TA TA |

| Bore | 6.7 in 170 mm |

| Stroke | 8.5 in 215 mm |

| Compression Ratio | 10.5:1 10.5:1 |

| Length | 290.35 in 7375 mm |

| Width | 72.05 in 1830 mm |

| Height | 96.97 in 2463 mm |

| Dry Weight - Genset | 52249.56 lb 23700 kg |

Advantages and Features

Cat G3520K Gas Engine

- Robust high speed block design provides prolonged life and lower owning operationg costs

- Designed for maximum performance on low pressure pipeline natural gas

- Simple open chamber combustion system for reliability and fuel flexibility

- Leading edge technology in ignition system and air/fuel ratio control for lower emission and engine efficiency

- One electronic control module handles all engine functions: ignition, governing, air/fuel ratio control and engine protection

SR5 Generator

- Designed to match performance and output characteristics of Caterpillar gas engines

- Industry leading mechanical and electrical design

- High efficiency

Cat Energy Control System (Cat ECS)

- A cost effective but powerful system

- Modern color touch screen

- Meets UL6200 controls and UL2300 3rd ed. generator set package requirements

- Local annunciation to meet NFPA 110

Emissions

- Meets most worldwide emissions requirements down to 0.5 g/bhp-hr Nox level without aftertreatment

Proven System

- Field proven in a wide range of applications worldwide

- Fully prototype tested

- Certified torsional vibration analysis available

Full Range of Attachments

- Wide range of bolt-on system expansion attachments

- Factory designed and tested

- Flexible packaging options for easy and cost effective installation

Worldwide Product Support

- Cat dealers have over 1,800 dealer branch stores operating in 200 countries

- Your local Cat dealer provides extensive post-sale support, including maintenance and repair agreements

Standard Equipment

-

Control Panel

- ECS 100 with colored HMI

- Ethernet Telematics

-

Air Inlet

- Two-element single-stage air cleaner with enclosure and service indicator.

-

Cooling

- Engine driven water pumps for jacket water and aftercooler.

- Jacket water and SCAC thermostats.

- ANSI/DN customer flange connections for JW inlet and outlet.

- SCAC control valve

-

Governing System

- ADEM A6 4-20mA (0-5V) Speed Input

-

Exhaust

- Center section cooled turbocharger with Cat flanged outlet.

- Dry exhaust manifolds, insulated and shielded.

- Individual exhaust port and turbocharger outlet wired to Integrated Tmeperature Sensing Module (ITSM) with GECM providing alarms and shutdowns.

-

Fuel System

- Electronic fuel metering valve

- Throttle plate, 24V DC actuator, controlled by GECM

- EN7462/CSAB149:3, NFPA37

- Fuel system is sized for 31.5 to 47.2 MJ/NM3 dry pipeline natural gas with pressure of 10.2 to 34.5KPa to the engine fuel control valve.

-

Generator

- IVR - Intergrated voltage regulator

- Crankshaft Vibration Damper and Guard

- Busbar connections

- Paint- Caterpillar Yellow except rails gloss black

- Winding temperature detectors

- Operation and maintenance manuals

- Parts book

- Anti-condensation space heater

- RH/LH Service

- SR5

- Reactive droop

-

Lube

- Electric Pre-lube pump

-

Starting/Charging

- 24V starting motors

-

Ignition System

- Electronic Ignition System (controlled by ADEM 6)

- In Cylinder Pressure Sensor (ICPS)

Optional Equipment

-

Control Panel

- ECS 200 with colored HMI

- Remote HMI displays

- Cellular telematics

- Expandable I/O

- Expandable Ethernet modules

- CAN 2 connection point

- Load Share Module

-

Lube

- Ship oil filled or dry(Ultra40)

- SYNHP (only ship dry)

- Oil Level Regulator

-

Starting/Charging

- Battery with cables and rack (shipped loose)

- Engine barring device

- Jacket water heater (220/400/240/480V)

- 60A, 24V charging alternator (requires engine driven pumps)

-

Circuit Breaker

- LSI/LSIG/LSIG-P Long-Time, Short-Time, Instantaneous Annunciator, ground fault protect, ground fault annunciate

- Non-par/Par Breakers

- Rear-mounted

- 5000A 3-Pole IEC/ULCSA Rated Circuit Breakers

-

Air Inlet

- Off Engine Air Cleaner - Mounting Brackets and Piping

-

Cooling

- Inlet/Outlet RH and LH connections

- Coolant level drain line with valves

-

Exhaust

- Muffler and spark-arresting muffler with companion flanges

- Flange, Elbow, and Flexible Fitting

- Exhaust Expander

-

Fuel System

- Gas Knockdown Regulator

- Fuel filter

- Gas pressure regulator

- Gas shutoff valve 24V, Energized-To-Run (ETR)

-

Generator

- Bearing temperature detectors

- Cable access box

- Low voltage extension box

- Manual voltage control

- NEMA/IEC Busbars

- Generator air filter

- Medium and high voltage generators and attachment

- Generator space heater (with optional heater control)

- Thermostate for space heater

- Current transformer, differential current transformer, potential transformer

-

General

- Digital diagnostic tool

- Special paint order

- Tool set

- US AID Emblem

-

Package

- Spring Isolators

- Seismic Isolators