Technicial Specifications

| Continuous Rating | 2300 ekW @1.0pf 2300 ekW @1.0pf |

| Fuel Type | Natural Gas, Biogas, Coal Gas, Hydrogen Blend (up to 25%) Natural Gas, Biogas, Coal Gas, Hydrogen Blend (up to 25%) |

| Maximum Electrical Efficiency | 45.00% 45.00% |

| Maximum Standby Rating | 2300 2300 |

| Frequency | 50/60 Hz 50/60 Hz |

| RPM | 1500 rpm 1500 rpm |

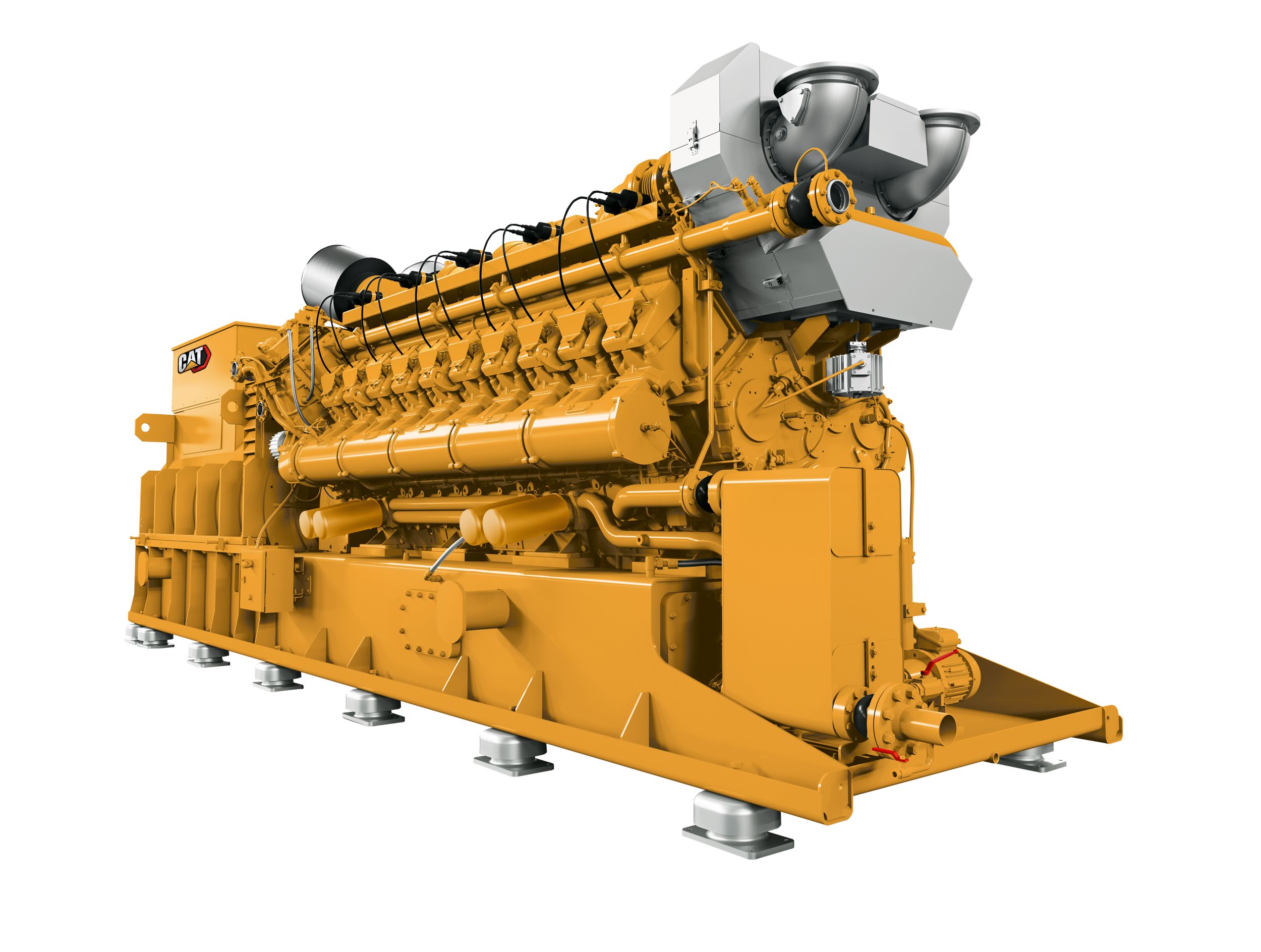

| Engine Model | CG170B-20 CG170B-20 |

| Aspiration | TA TA |

| Bore | 6.7 in 170 mm |

| Stroke | 7.7 in 195 mm |

| Length | 258 in 6556 mm |

| Width | 67 in 1706 mm |

| Height | 89 in 2263 mm |

| Dry Weight - Genset | 47377 lb 21490 kg |

Advantages and Features

High Efficiency, Lower Operating Costs

- Up to 45% electrical efficiency with Natural Gas

- 43.6% electrical efficiency with biogas

- Electrical output up to 2,300 kWel

- Reduced vibration and stress on components

Compact Size, High Profitability

- Compact design that delivers up to 15% more power output at the same size as its predecessor

- Long maintenance intervals (up to 80,000 hours)

- Available in different applications, such as natural gas, biogas, wellhead- and propane gas operation

- Maximum flexibility through different engine variants

Optimized Lubrication Consumption

- Consumes ~0.15g/kWh

- Reduced lube oil temperature through better cooling performance

- Savings of up to 3,000 liters of lube oil per year compared to comparable gensets

Standard Equipment

-

Air Inlet

- One-element single-stage air cleaner with enclosure and sevice indicator

- Turbocharger with a water-cooled bearing case for all cylinder

-

Control Panels

- TPEM (Total Plant & Energy Management System)

-

Cooling

- Jacket water and SCAC thermostats

- flange connections for JW inlet and outlet

- ANSI/DN customer flange connections for JW inlet and outlet

- Electrical jacket water and aftercooler coolant pump

-

Exhaust

- PEARL/Low resistence exhaust system

- Exhaust waste gate for the CG170B-20

- Closed crankcase ventilation system

-

Fuel system

- Pre-chamber spark plugs

- Electronic fuel metering valve

- Independently controlled cylinder monitoring and ignition system

-

Generator

- Busbar connections

- Winding temperature detectors

- grid code generator

- Reactive droop

- 3-phase sensing and KVAR/PF control

- Anti-condensation space heater

- closed-coupled generator result in no torque transmission to the base frame

-

Starting/Charging

- 24V starting motors

- Battery disconnect switch

-

General

- Crankshaft vibration damper and guard

Optional Equipment

-

Cooling

- CHP skid

-

Grid Code Compliance

- 50Hz: Germany, Belgium, Great Britain, Italy, Poland, and Netherlands