Texniki Xüsusiyyətlər

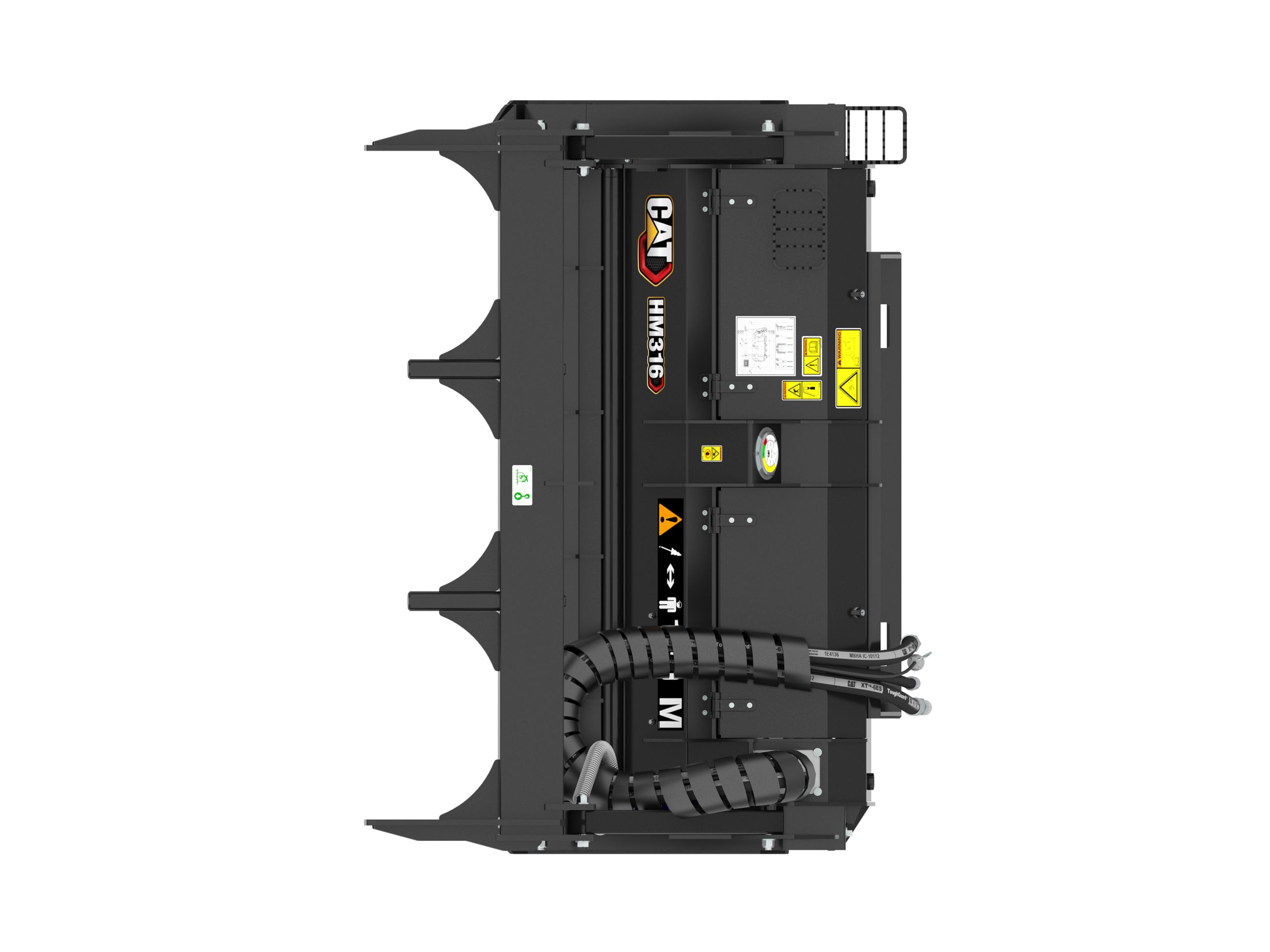

| Overall Width | 74.1 in 1882 mm |

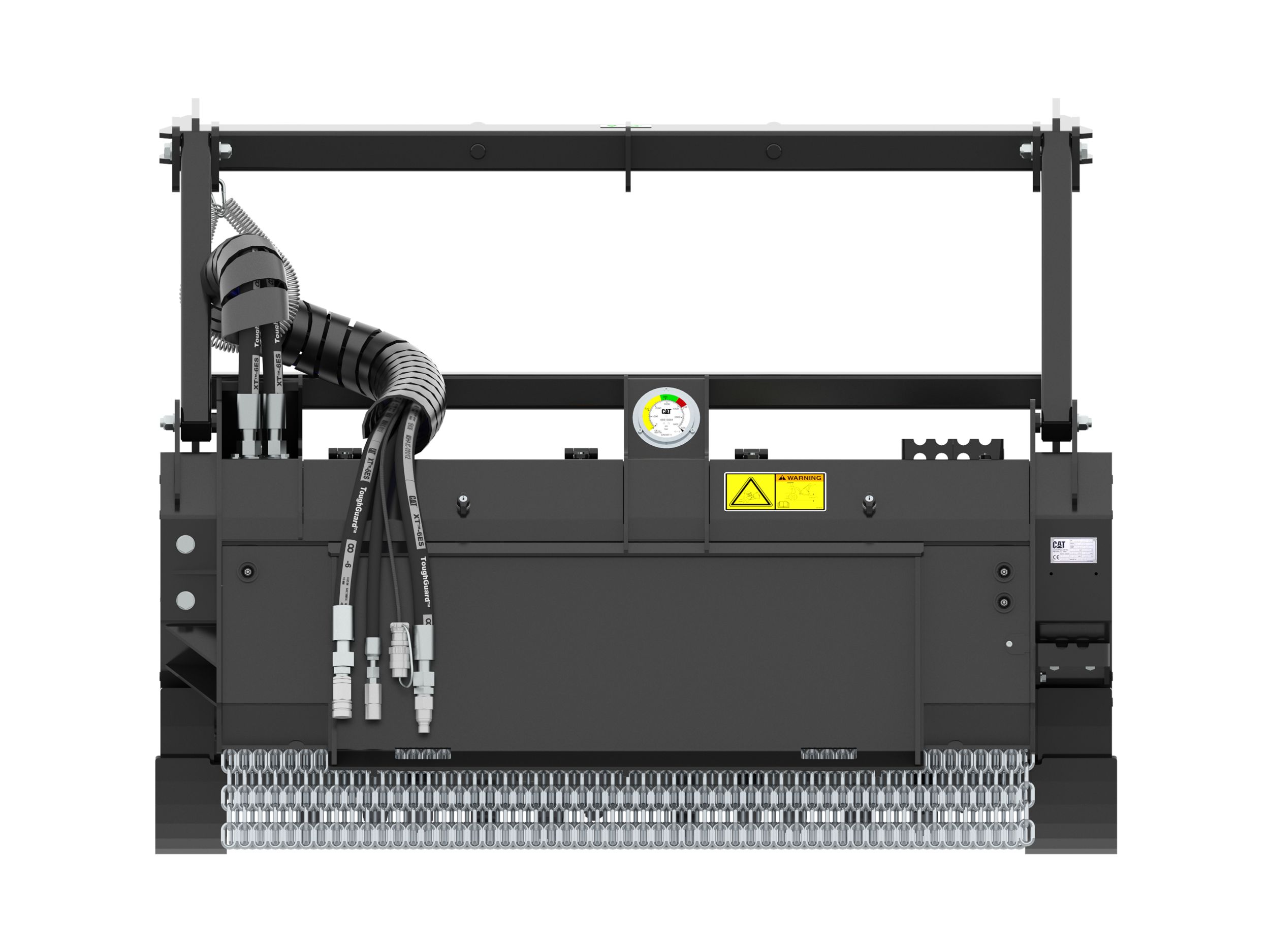

| Working Width | 62.3 in 1582 mm |

| Length | 53.3 in 1355 mm |

| Overall Height | 58.3 in 1481 mm |

| Weight | 2958.6 lb 1342 kg |

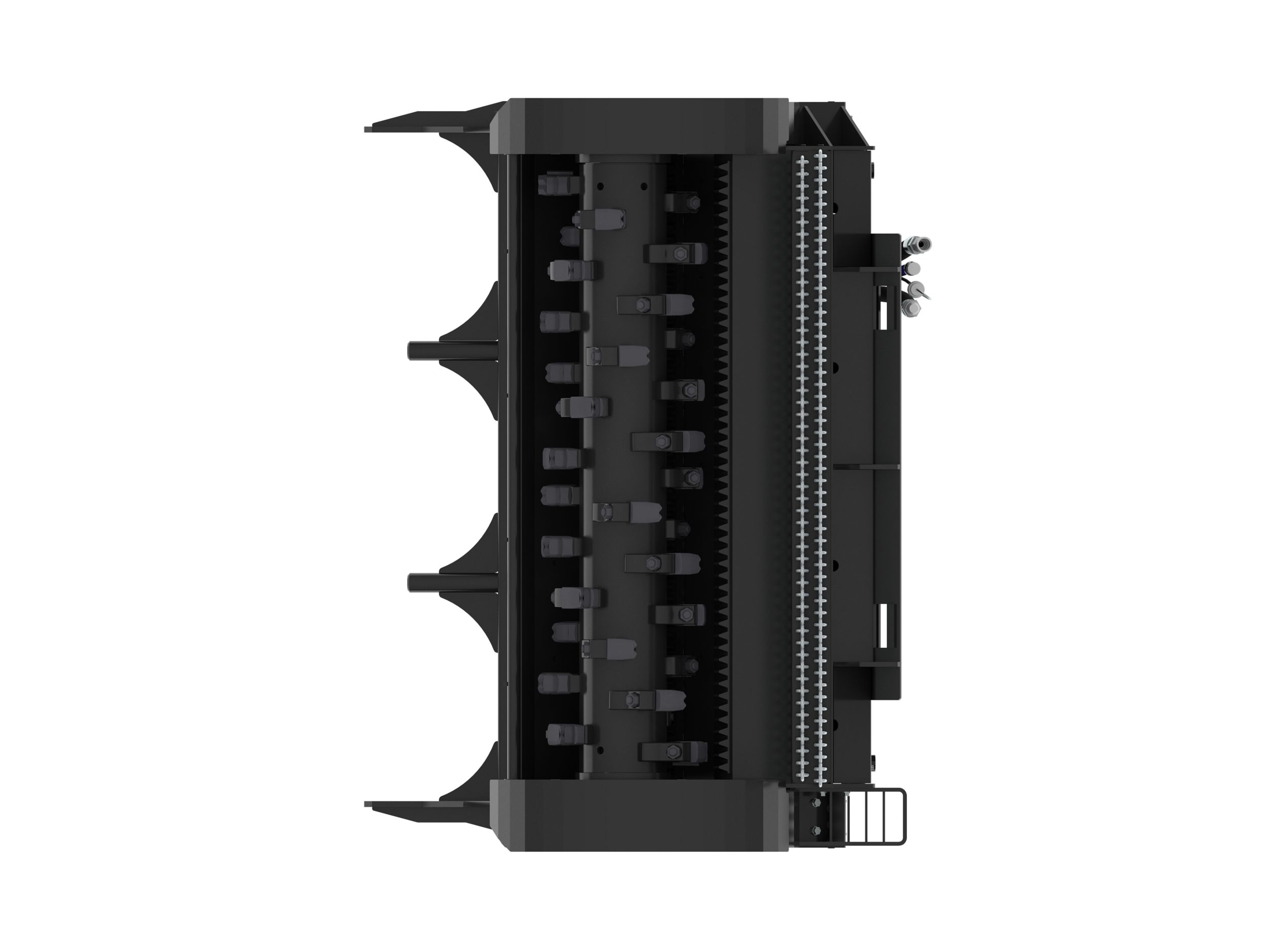

| Drive Method | Polychain Belt Polychain Belt |

| Motor | Axial Piston Dual Speed Axial Piston Dual Speed |

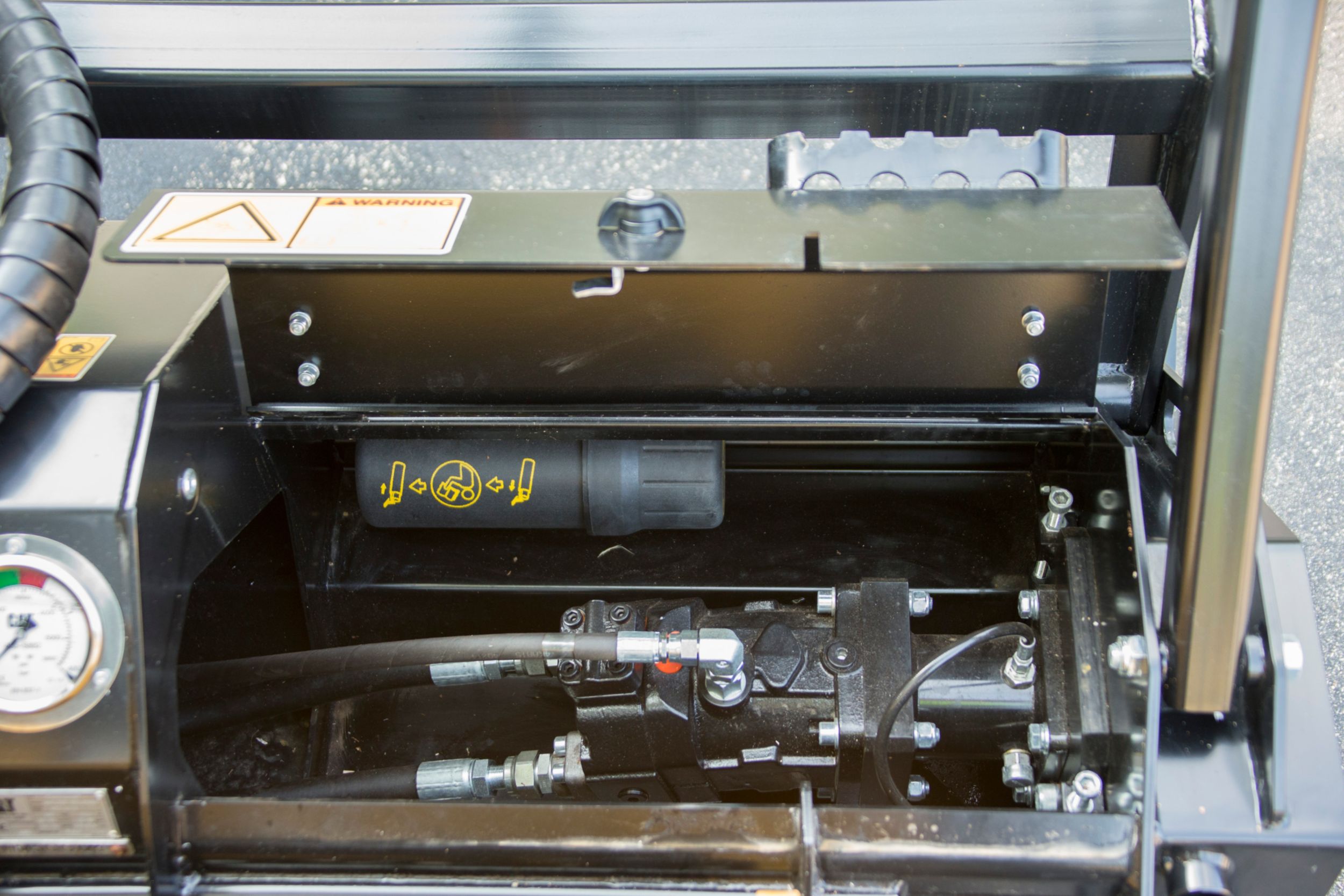

| Required Hydraulics | High Flow XPS High Flow XPS |

| Optimal Hydraulic Flow | 120-125 L/min (31-33 gpm) 120-125 L/min (31-33 gpm) |

| Optimal Hydraulic Pressure | 200-280 bar (2900-4061 psi) 200-280 bar (2900-4061 psi) |

| Drum Speed | 2100-2400 RPM 2100-2400 RPM |

| Fixed Teeth per Drum | 34 34 |

| Maximum Cutting Diameter | 7.9 in 200 mm |

| Maximum Cutting Depth | 4.1 in 105 mm |