Teknik Özellikler

| Net Power - ISO 9249 | 225 hp 168 kW |

| Emissions | Tier 4/Stage V Tier 4/Stage V |

| Displacement | 428 in³ 7.01 l |

| Maximum Net Power - 1,700 rpm - ISO 9249 - Metric | 228 hp 168 kW |

| Maximum Power - 1,700 rpm - ISO 14396 | 240 hp 179 kW |

| Maximum Power - 1,700 rpm - ISO 14396 - Metric | 243 hp 179 kW |

| Peak Gross Torque - 1,400 rpm - SAE J1995 | 811 ft·lbf 1099 N·m |

| Peak Gross Torque - 1,400 rpm - ISO 14396 | 805 ft·lbf 1092 N·m |

| Engine Model | Cat C7.1 Cat C7.1 |

| Maximum Net Power - 1,700 rpm - ISO 9249 | 225 hp 168 kW |

| Maximum Net Power - 1,700 rpm - SAE J1349 | 225 hp 168 kW |

| Maximum Power - 1,700 rpm - SAE J1995 | 241 hp 180 kW |

| Note | The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1.9 kg (4.2 lb) of refrigerant which has a CO2 equivalent of 2.717 metric tonnes (2.995 tons). The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1.9 kg (4.2 lb) of refrigerant which has a CO2 equivalent of 2.717 metric tonnes (2.995 tons). |

| Bore | 4.13 in 105 mm |

| Stroke | 5.31 in 135 mm |

| Operating Weight | 41554 lb 18849 kg |

| Bucket Capacities | 2.9-4.4 m³ (3.75-5.75 yd³) 2.9-4.4 m³ (3.75-5.75 yd³) |

| Reverse - 3 | 14.2 mile/h 22.8 km/h |

| Forward - 3 | 14.2 mile/h 22.8 km/h |

| Forward - 1 | 4.5 mile/h 7.3 km/h |

| Forward - 2 | 8 mile/h 12.8 km/h |

| Forward - 4 | 22.4 mile/h 36 km/h |

| Reverse - 2 | 8 mile/h 12.8 km/h |

| Reverse - 1 | 4.5 mile/h 7.3 km/h |

| Note | Maximum travel speed in standard vehicle with empty bucket and standard L3 tires with 760 mm (30 in) roll radius. Maximum travel speed in standard vehicle with empty bucket and standard L3 tires with 760 mm (30 in) roll radius. |

| Hydraulic Cycle Time - Total Cycle Time | 9.4 s 9.4 s |

| Steering System - Pump Type | Piston Piston |

| Implement System - Maximum Operating Pressure @ 50 ± 1.5 L/min (13.2 + 0.4 gal/min) | 4047 psi 27900 kPa |

| Implement System - Maximum Pump Output at 2,390 rpm | 68 gal/min 256 l/min |

| DEF Tank | 4.2 gal (US) 16 l |

| Transmission | 11.9 gal (US) 45 l |

| Fuel Tank Size | 76.6 gal (US) 290 l |

| Cooling System | 13.2 gal (US) 50 l |

| Differential - Final Drives - Rear | 10 gal (US) 38 l |

| Differential - Final Drives - Front | 10.6 gal (US) 40 l |

| Crankcase | 4.8 gal (US) 18 l |

| Hydraulic Tank | 29.6 gal (US) 112 l |

| With Cooling Fan Speed at Maximum Value - Operator Sound Pressure Level (ISO 6396:2008) | 73 dB(A) 73 dB(A) |

| With Cooling Fan Speed at Maximum Value - Exterior Sound Power Level (ISO 6395:2008) | 109 dB(A) 109 dB(A) |

| With Cooling Fan Speed at Maximum Value - Exterior Sound Pressure Level (SAE J88:2013) | 76 dB(A)* 76 dB(A)* |

| Note (1) | *Distance of 15 m (49.2 ft), moving forward in second gear ratio. *Distance of 15 m (49.2 ft), moving forward in second gear ratio. |

| With Cooling Fan Speed at 70% of Maximum Value: Note (2) | European Union Directive "2000/14/EC" as amended by "2005/88/EC." European Union Directive "2000/14/EC" as amended by "2005/88/EC." |

| With Cooling Fan Speed at 70% of Maximum Value - Operator Sound Pressure Level (ISO 6396:2008)** | 73 dB(A) 73 dB(A) |

| With Cooling Fan Speed at 70% of Maximum Value: Note (1) | For machines in European Union countries and in countries that adopt the EU Directives For machines in European Union countries and in countries that adopt the EU Directives |

| With Cooling Fan Speed at Maximum Value - Note | Distance of 15 m (49.2 ft), moving forward in second gear ratio. Distance of 15 m (49.2 ft), moving forward in second gear ratio. |

| With Cooling Fan Speed at 70% of Maximum Value - Exterior Sound Power Level (ISO 6395:2008)** | 107 LWA*** 107 LWA*** |

| Note (3) | ***European Union Directive "2000/14/EC" as amended by "2005/88/EC." ***European Union Directive "2000/14/EC" as amended by "2005/88/EC." |

| Note (2) | **For machines in European Union countries and in countries that adopt the "EU Directives." **For machines in European Union countries and in countries that adopt the "EU Directives." |

| Rack Back - Ground | 40 degrees 40 degrees |

| Height - Top of Exhaust Pipe | 11.17 ft 3416 mm |

| Centerline of Rear Axle to Hitch | 5.42 ft 1650 mm |

| Lift Arm Clearance | 12 ft 3649 mm |

| B-Pin Height | 13.75 ft 4188 mm |

| Centerline of Rear Axle to Edge of Counterweight | 6.75 ft 2055 mm |

| Ground Clearance | 1.5 ft 460 mm |

| Rack Back - Maximum Lift | 60 degrees 60 degrees |

| Height - Top of Hood | 8.75 ft 2673 mm |

| Wheel Base | 10.83 ft 3300 mm |

| Height - Top of ROPS | 11.33 ft 3458 mm |

| Rack Back - Carry | 45 degrees 45 degrees |

| Note | All dimensions are approximate and based on MAXAM MS302 23.5R25 L3 radial tires. All dimensions are approximate and based on MAXAM MS302 23.5R25 L3 radial tires. |

| Note (2) | *Full compliance to ISO (2007) 14397-1 Sections 1 thru 6, which requires 2% verification between calculations and testing. *Full compliance to ISO (2007) 14397-1 Sections 1 thru 6, which requires 2% verification between calculations and testing. |

| Tipping Load - Full Turn - Rigid Tires** | 25875 lb 11737 kg |

| Breakout Force | 34638 lbf 154 kN |

| Tipping Load - Full Turn - ISO 14397-1* | 24264 lb 11006 kg |

| Note (3) | **Compliance to ISO (2007) 14397-1 Sections 1 thru 5. **Compliance to ISO (2007) 14397-1 Sections 1 thru 5. |

| Operating Weight | 41554 lb 18849 kg |

| Note (1) | For 3.1 m3 (4.0 yd3) general purpose buckets with BOCE. Weight based on a machine configuration with MAXAM MS302 23.5R25 L3 radial tires, full fluids, operator, standard counterweight, cold start, roading fenders, Product Link™, secondary steering, sound suppression. For 3.1 m3 (4.0 yd3) general purpose buckets with BOCE. Weight based on a machine configuration with MAXAM MS302 23.5R25 L3 radial tires, full fluids, operator, standard counterweight, cold start, roading fenders, Product Link™, secondary steering, sound suppression. |

| Emissions | Tier 4/Stage IV Tier 4/Stage IV |

Avantaj ve Özellikler

RELIABILITY YOU CAN COUNT ON

- Cat® C7.1 engine offers increased power density with a combination of proven electronic, fuel, and air systems.

- Equipped with automatic Cat regeneration system, Cat Clean Emissions Module (CEM) with Diesel Particulate Filter (DPF), and Diesel Exhaust Fluid (DEF) tank and pump.

- Thorough component design and machine validation processes result in unmatched reliability and uptime.

ACHIEVE GREATER PRODUCTIVITY

- The proven Cat Z-bar linkage geometry with Performance Series Buckets offer excellent penetration into the pile and high breakout forces. Combined with best-in-class standard dump clearan ce, this results in low fuel consumption and exceptional production capabilities.

- Cat designed, electronically controlled, automatic powershiftcountershaft transmission features shift protection and is equipped with a split flow oil system for efficiency, durability, and smoother gear changes.

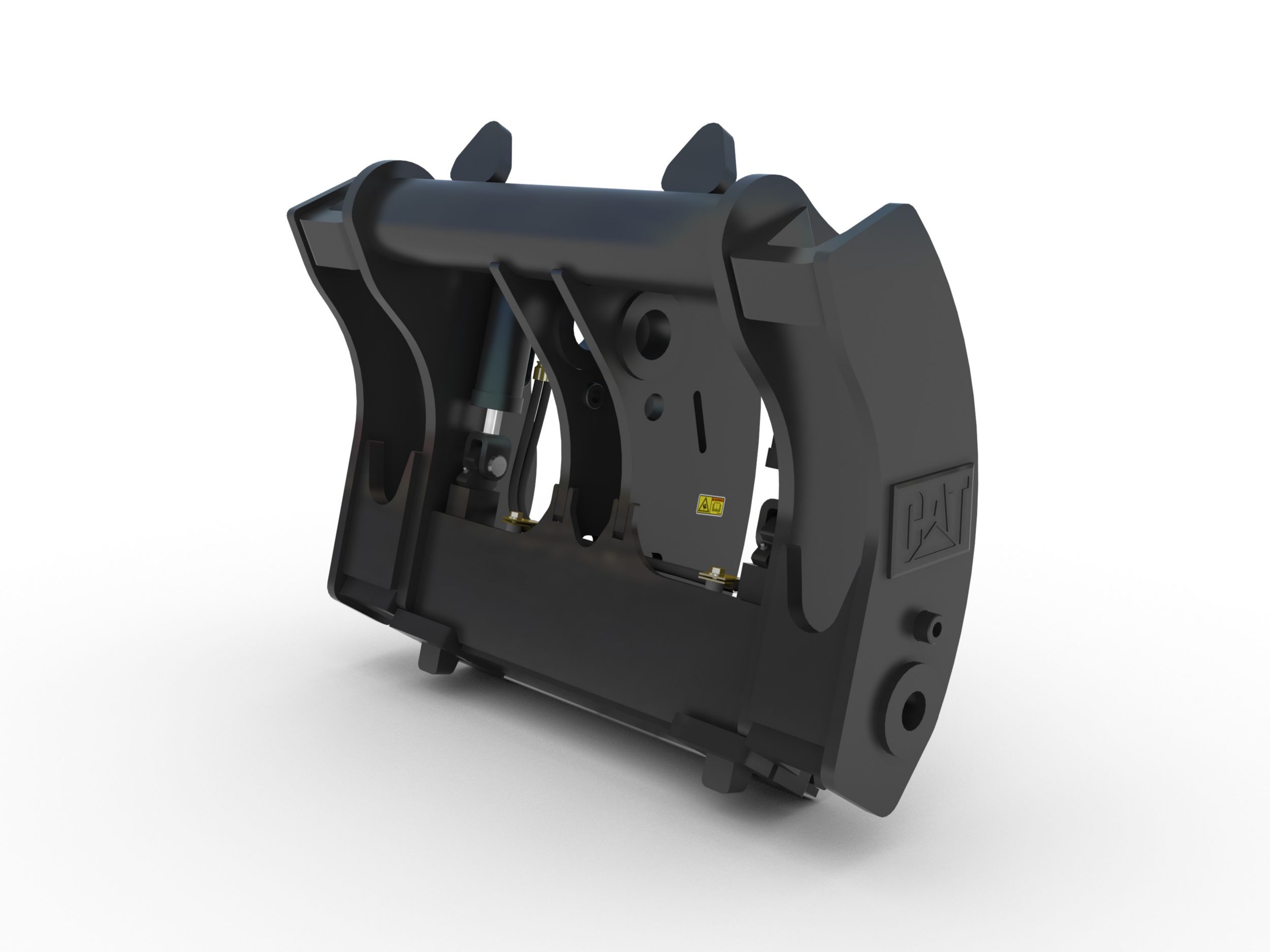

- Optional Fusion™ quick-coupler control features a selectable kickout to adjust for efficient bucket and fork applications.

DO MORE WITH LESS FUEL

- Engine Idle Management System (EIMS) and Auto Engine Idle Shutdown (EIS) maximize fuel efficiency by reducing engine rpm after a specified amount of idle time.

- Electronically controlled, hydraulically driven variable speed fan adjusts to meet the varying cooling requirements of the machine. This results in a reduced average fan speed, lowering fuel consumption, noise levels, and radiator plugging.

- Load sensing hydraulics produce flow and pressure for theimplement system upon demand and only in amounts necessary to perform the needed work functions. This state-of-the-art system results in low fuel consumption.

DESIGNED FOR OPERATORS

- The spacious cab features easy, intuitive controls and excellent visibility which provides a comfortable working environment for efficient all day operation.

- Pilot-operated hydraulic implement controls deliver comfortable, low-effort operation. Two single-axis levers or one joystick are available. Both arrangements are equipped with kick-down switches.

- The adjustable steering column includes the F-N-R shifter and turn signal control lever.

- Unmatched viewing area with a wide, flat, and distortion-free front windshield.

- The glass stretches to the floor of the cab for excellent visibility to the bucket and front tires.

- The cab roof has channels which direct rain off the corners of the cab, keeping windows clear.

- Air conditioning system is standard. Ten louvered vents allow the operator to direct the air flow to remain productive and efficient all shift long.

SAFELY HOME EVERY DAY

- Ladders are standard on both sides of the machine to easily access the platforms.

- Platforms are equipped with guard- and handrails for safe access to the cab.

- The main cab door opens to the front and provides wide access to the operator environment.

- Front and back wipers ensure that a clear view is maintained.

- External rearview mirrors with integrated spot mirrors arestandard.

- A rear vision camera is standard to clearly monitor movement behind the machine.

- Hinged wheel guards, easy removal/re-install.

- Optional windshield and power train guards.

SAVE ON SERVICE AND MAINTENANCE

- Grouped service points and sight gauges allow for easy daily maintenance.

- Convenient access to left, right, and rear of engine compartment provides excellent serviceability.

- Electrical and hydraulic service centers, along with additional key serviceability features, help make servicing and in-field component exchange quick, easy, and efficient.

- A rear swing-up grill gives easy cleaning access to thecooling cores.

- Optional integrated Cat Autolube system provides full lube system monitoring and diagnostic test visibility. One-button control, including fault flash function.

- Caterpillar design and manufacturing techniques assureoutstanding service life.

CAT PRODUCTION MEASURMENT KIT

- This optional kit is simple to install compared to other 3rd party payload systems*.

- On-the-go weighing** for precise load targets with provenaccuracy, flexible installation, and easy calibration and setup.

- Brings payload weighing to the cab so operators can work more productively and deliver consistently accurate loads.

- Increases productivity, weighing while lifting with no interruptions in loading cycle.

- High efficiency: load to exact specification, load more trucks faster, and move more material for more revenue.

- Improve efficiency with less rework; save time, labor, fuel,and costs.

* Not available in all markets

** Not legal for trade

Standart Donanımlar

-

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

POWER TRAIN

- Engine - Cat C7.1 meets Tier 4 Final/Stage IV emissions standards

- Torque converter

- Transmission, automatic, power shift (4F/3R), kick-down function, overspeed protection

- Brakes, full hydraulic enclosed wet-disc

- EIMS (Engine Idle Management System)

- EIS (Auto Idle Shutdown)

- Fan, radiator, electronically controlled, hydraulically driven, temperature sensing, on demand

- Filter, fuel primary-water separator/secondary

- Radiator, unit core (9.5 fpi) with ATAAC

- Starting aid, glow plugs

- Switch, transmission neutralizer lockout

-

HYDRAULICS

- Load sensing implement system pilot operated

- Dedicated load sensing steering pump

- Dedicated brake and fan gear pump

-

ELECTRICAL

- Alarm, back-up/main disconnect switch

- Alternator (145-amp, brush type)

- Batteries (2), maintenance free

- Ignition key; start/stop switch

- Lighting system, halogen (6 total) - Four (4) halogen work lights; Two (2) halogen road lights

- Starting and charging system (24-volt)

- Starter, electric (heavy duty)

-

OPERATOR ENVIRONMENT

- Air conditioning (HVAC) with 10 vents and filter unit located outside of cab

- Bucket/work tool function lockout

- Cab, pressurized and sound suppressed

- Hydroformed (ROPS/FOPS) structure

- 12V power port (10A)

- Coat hook

- Radio ready

- Rear vision camera and display

- Pilot hydraulic controls, lift and tilt function

- Computerized monitoring system

- Gauges - Engine coolant temperatures/fluid level; Hydraulic/transmission oil temperature; Tachometer/DEF level

- Digital indicators - Gear indicator; Speedometer; Service meter units; Fault codes

- Warning indicators - Air inlet heater; Electrical malfunction; Engine inlet manifold temperature; Engine oil pressure, fuel level; Fuel pressure high/low; Hydraulic oil level, parking brake; Primary steering oil pressure; Service brake oil pressure; Action light, engine malfunction; Transmission filter bypass

- Heater and defroster

- Horn

- Cup holders and personal tray on right console

- Storage tray behind seat

- Mirrors, rearview external

- Seat, Cat Comfort (clotch) suspension

- Seat belt

- Steering column, adjustable angle

- Wipers/washers (front and rear)

- Window, sliding (left and right side)

-

TIRES, RIMS, AND WHEELS

- Tires are available from Triangle, Maxam and Bridgestone

- Offerings vary by region. Consult your local Cat dealer for further details

-

FLUIDS

- Premixed 50% concentration of extended life coolant with freeze protection to -34° C (-29° F)

-

OTHER STANDARD EQUIPMENT

- Lift and bucket return-to-dig kick outs (Electro-Magnetic), mechanical adjustment

- Couplings, Cat O-ring face seal

- Doors, service access (locking)

- Front fender, steel

- Grill, airborne debris

- Hitch, drawbar with pin

- Hood, wing doors

- Hoses, Cat XT

- Counterweight

- Linkage, Z-bar, fabricated crosstube/tilt lever

- S•O•S oil sampling valves

- Sight gauges - Engine coolant, hydraulic oil; Transmission oil level

- Diagnostic pressure taps

- Product Link Ready

İsteğe Bağlı Donanımlar

-

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

OPTIONAL EQUIPMENT

- Cold weather starting (jacket water heater, electric and ether starting aid)

- Third hydraulic function, additional dedicated single axis level

- Quick coupler control

- Limited slip differentials

- Ride control

- Air suspended seat

- Secondary steering, electrical

- Reversing cooling fan (auto/manual controlled)

- Toolbox

- Sun visor, rear

- High capacity converted 12V/15A

- Warning beacon

- Extra working lights (4), Halogen or LED

- Radio

- Fender extensions/roading