Texniki Xüsusiyyətlər

| Maximum Gross Power | 74.7 hp 55.7 kW |

| Engine Model | Cat C2.8* Cat C2.8* |

| Maximum Engine Speed | 2550 rpm 2550 rpm |

| Maximum Gross Power - Rated Engine Speed | 2400 r/min 2400 r/min |

| Maximum Gross Power - SAE J1995 | 74.7 hp 55.7 kW |

| Maximum Gross Power - ISO 14396 | 74.3 hp 55.4 kW |

| Maximum Gross Power - ISO 14396 (metric) | 75.3 mhp 75.3 mhp |

| Rated Net Power - Rated Engine Speed | 2400 r/min 2400 r/min |

| Rated Net Power - SAE J1349 | 72.7 hp 54.2 kW |

| Rated Net Power - ISO 9249 | 72.1 hp 53.8 kW |

| Rated Net Power - 2,400 rpm - ISO 9249 (metric) | 73.1 mhp 73.1 mhp |

| Maximum Gross Torque - SAE J1995 | 222 lb/ft 300 N·m |

| Maximum Gross Torque - ISO 14396 | 221 lb/ft 300 N·m |

| Maximum Net Torque - SAE J1349 | 218 lb/ft 296 N·m |

| Maximum Net Torque - ISO 9249 | 217 lb/ft 295 N·m |

| Displacement | 171 in³ 2.8 l |

| Bore | 3.54 in 90 mm |

| Stroke | 4.33 in 110 mm |

| Note | Advertised power is tested per the specified standard in effect at the time of manufacture. Advertised power is tested per the specified standard in effect at the time of manufacture. |

| Note (1) | Net power advertised is the power available at the flywheel. Net power advertised is the power available at the flywheel. |

| Note (2) | *Two Cat C2.8 engine emission options are available: 1) Meets U.S. EPA Tier 4 Final, EU Stage V. 2) U.S. EPA Tier 3 and EU Stage IIIA equivalent. Tier 3 engine specs are 0.3 kW/0.4 hp more gross power (SAE J1995), 0.2 kW/0.3 hp on net power (SAE J1349) and 1 N·m/0.7 lb-ft higher on gross torque (SAE J1995). *Two Cat C2.8 engine emission options are available: 1) Meets U.S. EPA Tier 4 Final, EU Stage V. 2) U.S. EPA Tier 3 and EU Stage IIIA equivalent. Tier 3 engine specs are 0.3 kW/0.4 hp more gross power (SAE J1995), 0.2 kW/0.3 hp on net power (SAE J1349) and 1 N·m/0.7 lb-ft higher on gross torque (SAE J1995). |

| Note (3) | Maximum gross and net torque measured at 1,600 rpm. Maximum gross and net torque measured at 1,600 rpm. |

| Operating Weight | 12628 lb 5730 kg |

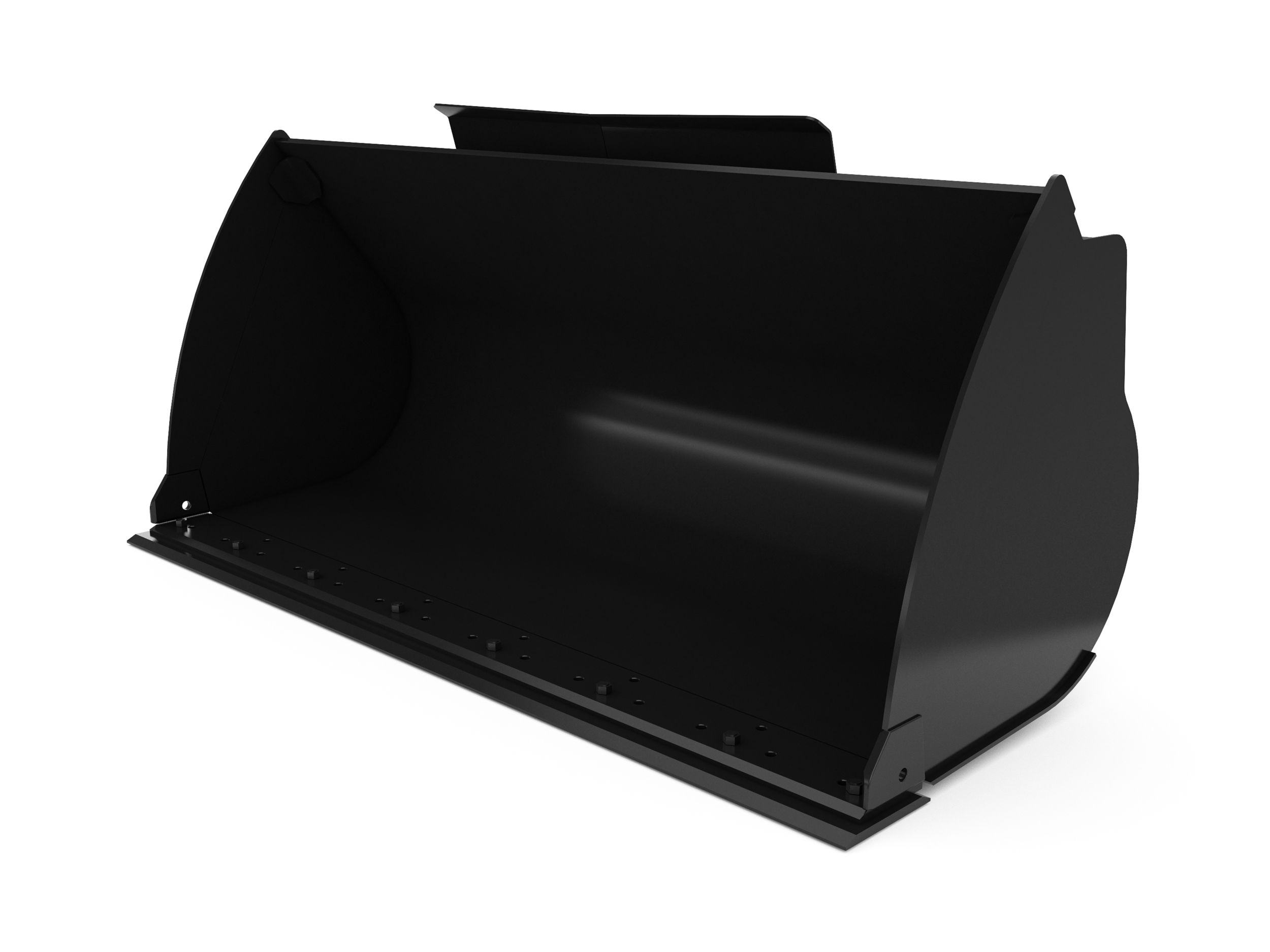

| Bucket Capacities | 0.75-1.55 m³ (1.0-2.0 yd³) 0.75-1.55 m³ (1.0-2.0 yd³) |

| Bucket Capacities - General Purpose | 0.80-1.35 m³ (1.0-1.7 yd³) 0.80-1.35 m³ (1.0-1.7 yd³) |

| Bucket Capacities - Light Material | 1.25-1.55 m³ (1.6-2.0 yd³) 1.25-1.55 m³ (1.6-2.0 yd³) |

| Multi-Purpose | 0.75-1.1 m³ (1.0-1.4 yd³) 0.75-1.1 m³ (1.0-1.4 yd³) |

| Note | Bucket selection must be made with an understanding of the material density and application to ensure machine stability is maintained within the tipping loads stated per model and configuration. Bucket selection must be made with an understanding of the material density and application to ensure machine stability is maintained within the tipping loads stated per model and configuration. |

| Note (1) | Bucket capacities stated include BOCE, in line with ISO 7546. Bucket capacities stated include BOCE, in line with ISO 7546. |

| Recyclability | 93% 93% |

| Fuel Tank | 18.5 Gal 70 l |

| Cooling System | 3.2 Gal 12 l |

| Engine Crankcase | 2.3 Gal 8.8 l |

| Axles - Front Center Differential | 2.3 Gal 8.8 l |

| Axles - Rear Center Differential | 2.3 Gal 8.8 l |

| Hydraulic System - Including Tank | 17.8 Gal 67.5 l |

| Hydraulic Tank | 11.8 Gal 44.6 l |

| Transmission | 0.6 Gal 2.4 l |

| Note | No Diesel Exhaust Fluid (DEF) fluid needed on this size engine. No Diesel Exhaust Fluid (DEF) fluid needed on this size engine. |

| Front | Fixed (standard) Locking Differential (optional) Fixed (standard) Locking Differential (optional) |

| Rear | Fixed (standard) Locking Differential (optional) Fixed (standard) Locking Differential (optional) |

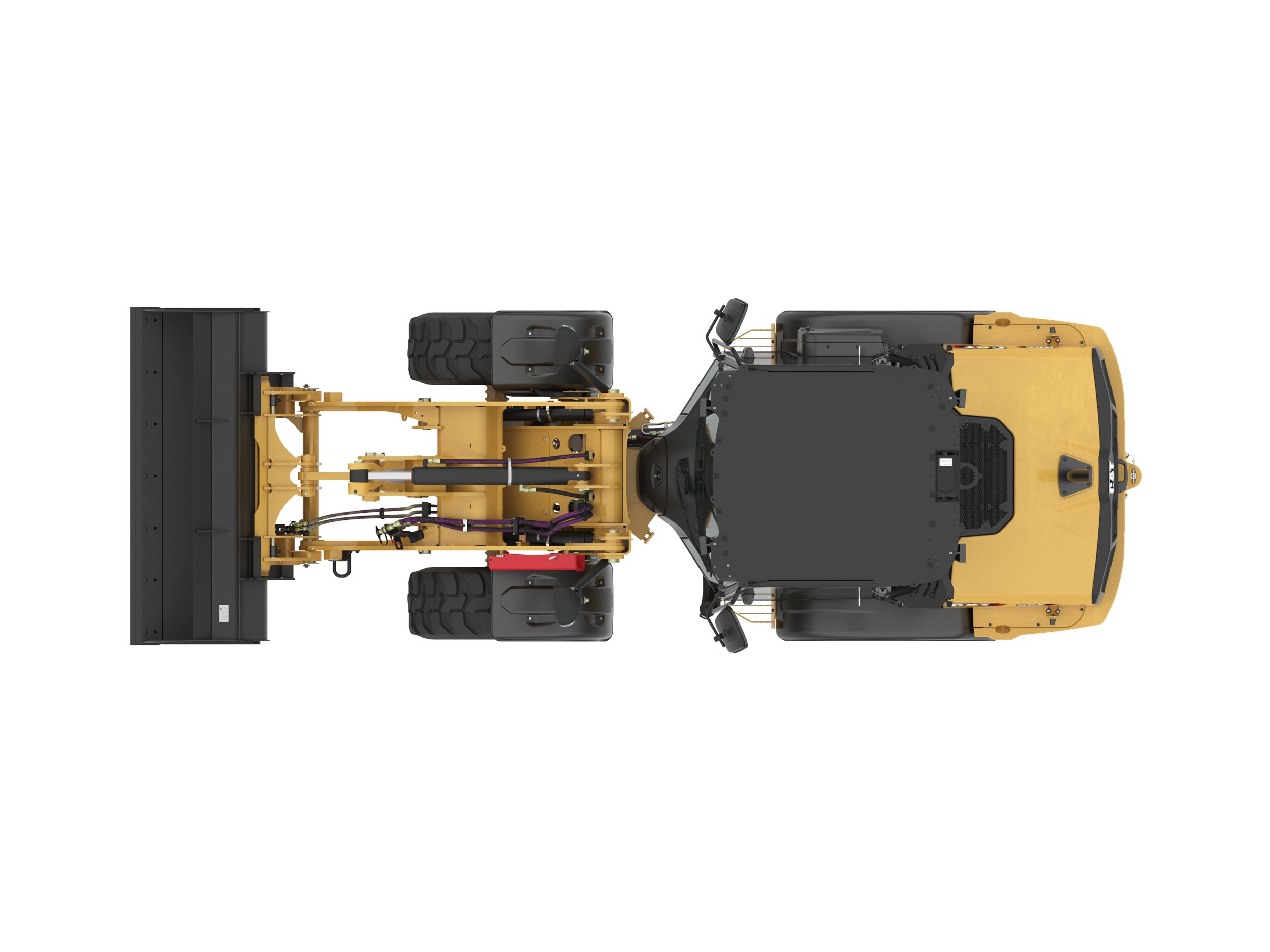

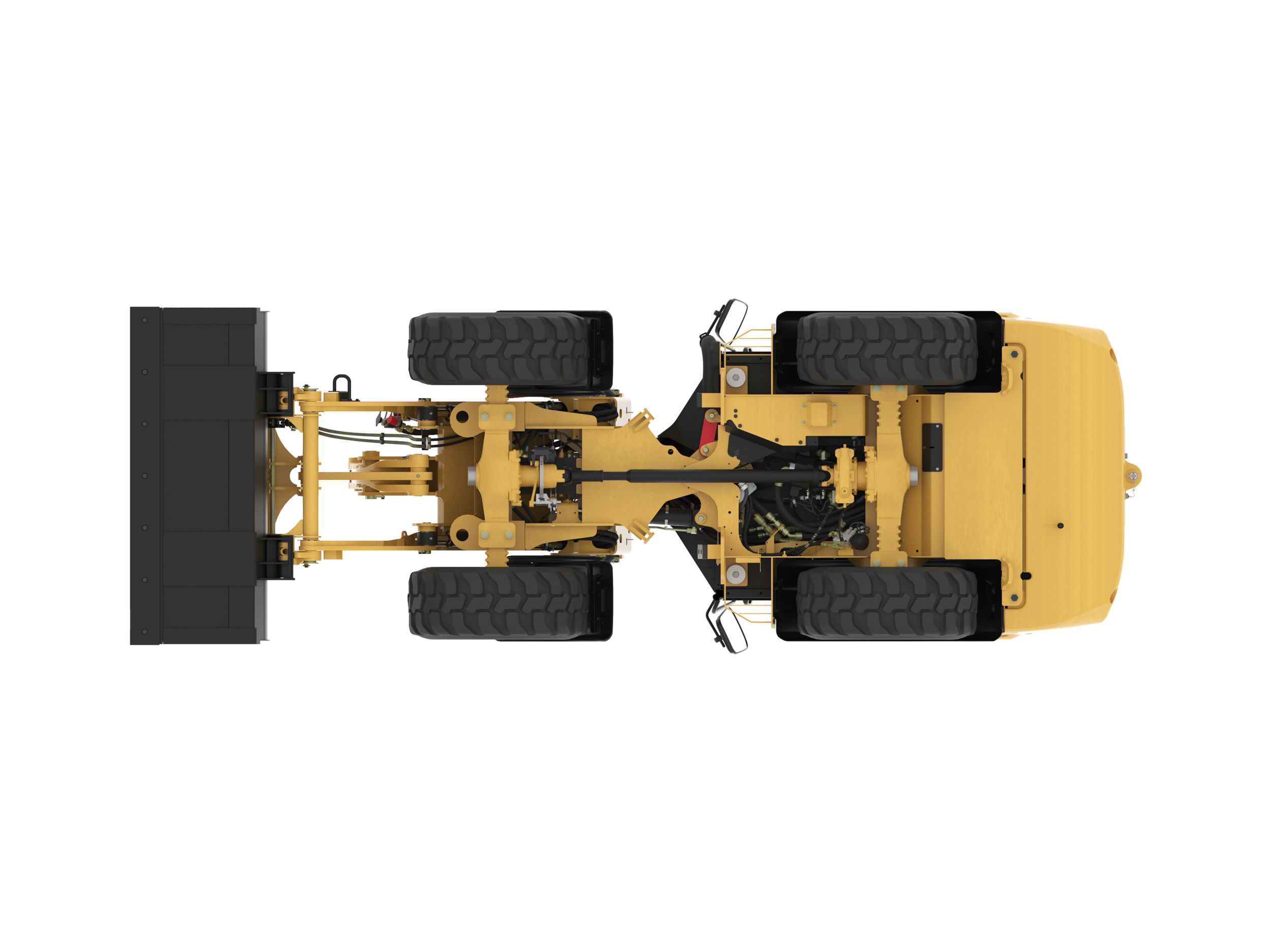

| Note | Oscillation of ±11 degrees via hitch between front and rear frames. Oscillation of ±11 degrees via hitch between front and rear frames. |

| Steering Articulation Angle - Each Direction | 39 ° 39 ° |

| Maximum Flow - Steering Pump | 12.3 gal/min 46.7 l/min |

| Maximum Working Pressure - Steering Pump | 3336 psi 23000 kPa |

| Steering Cycle Times – (full left to full right) – at High Idle | 2.8 s 2.8 s |

| Number of Steering Wheel Turns - Full Left to Full Right or Full Right to Full Left | 3.25 turns or 4.00 turns 3.25 turns or 4.00 turns |

| Forward and Reverse - Speed Range Creep# | 6 mile/h 10 km/h |

| Forward and Reverse - Speed Range 1* | 6 mile/h 10 km/h |

| Forward and Reverse - Speed Range 2** - High Speed | 10.5 mile/h 17 km/h |

| Forward and Reverse - Speed Range 2** - Standard | 12 mile/h 20 km/h |

| Forward and Reverse - Speed Range 3*** | 25 mile/h 40 km/h |

| Note | Factory default shown, can be adjusted to any speed up to 19 km/h (12 mph). Factory default shown, can be adjusted to any speed up to 19 km/h (12 mph). |

| Note (1) | *Creep function not available in this gear or above. *Creep function not available in this gear or above. |

| Note (2) | **Max speed dependent on model and configuration (standard vs. high speed transmission). **Max speed dependent on model and configuration (standard vs. high speed transmission). |

| Note (3) | ***Reverse is 30 km/h (19 mph). ***Reverse is 30 km/h (19 mph). |

| Tire Size - Standard | *405/70 R18 SPT9 *405/70 R18 SPT9 |

| Tire Size - Optional | 405/70 R18 Powerloads 405/70 R18 Powerloads |

| Tire Size - Optional (1) | 340/80 R18 XMCL/Bibload 340/80 R18 XMCL/Bibload |

| Tire Size - Optional (2) | 340/80 R18 TRI 2 340/80 R18 TRI 2 |

| Tire Size - Optional (3) | 40X14-20 TL, SM/TR 40X14-20 TL, SM/TR |

| Tire Size - Optional 4 | 340/80 R18 Duraforce 340/80 R18 Duraforce |

| Note | *This tire has been used for all dimension, stability and performance data. *This tire has been used for all dimension, stability and performance data. |

| Note (1) | Other tire choices are available. Contact your Cat dealer for details. Other tire choices are available. Contact your Cat dealer for details. |

| Note (2) | In certain applications, the loader’s productive capabilities may exceed the tire’s tonnes-km/h (ton-mph) capabilities. In certain applications, the loader’s productive capabilities may exceed the tire’s tonnes-km/h (ton-mph) capabilities. |

| Note (3) | Caterpillar recommends that you consult a tire supplier to evaluate all conditions before selecting a tire model. Caterpillar recommends that you consult a tire supplier to evaluate all conditions before selecting a tire model. |

| ROPS | ISO 3471:2008 ISO 3471:2008 |

| FOPS | ISO 3449:2005 Level II ISO 3449:2005 Level II |

| Note (1) | Canopy and cab, Rollover Protective Structures (ROPS) are available worldwide. Canopy not available in EU. Canopy and cab, Rollover Protective Structures (ROPS) are available worldwide. Canopy not available in EU. |

| Main Relief - 1st Auxiliary (3rd slice) | 3408 psi 23500 kPa |

| Main Relief - 1st Auxiliary (3rd slice) - Standard Flow* | 21 gal/min 80 l/min |

| Main Relief - 1st Auxiliary (3rd slice) - High Flow* | 32 gal/min 120 l/min |

| Main Relief - 2nd Auxiliary (4th slice) | 3408 psi 23500 kPa |

| Main Relief - 2nd Auxiliary (4th slice) - Flow | 12 gal/min 45 l/min |

| Hydraulic Cycle Time - Rackback | 2.2 s 2.2 s |

| Hydraulic Cycle Time - Lift | 5 s 5 s |

| Hydraulic Cycle Time - Dump | 1.6 s 1.6 s |

| Hydraulic Cycle Time - Float Down | 2.8 s 2.8 s |

| Note | * Maximum flow stated, actual flow delta could be 6% from data shown. Also adjustable from 20% to 100% of maximum flow through display. * Maximum flow stated, actual flow delta could be 6% from data shown. Also adjustable from 20% to 100% of maximum flow through display. |

| Height: Ground to Cab** | 8.08 ft 2468 mm |

| Height: Ground to Beacon** | 8.67 ft 2651 mm |

| Height: Ground Axle Center** | 1.58 ft 480 mm |

| Height: Ground Clearance** | 1 ft 300 mm |

| Length: Overall* | 17.58 ft 5369 mm |

| Length: Rear Axle to Bumper | 4.58 ft 1391 mm |

| Length: Hitch to Front Axle | 3.58 ft 1085 mm |

| Length: Wheel Base | 7.08 ft 2170 mm |

| Clearance: Bucket at 45° * | 8.25 ft 2510 mm |

| Clearance: Load over Height** | 9.5 ft 2902 mm |

| Clearance: Level Bucket** | 9.92 ft 3037 mm |

| Height: Bucket Pin** | 10.67 ft 3251 mm |

| Height: Overall** | 13.5 ft 4122 mm |

| Reach: Bucket at 45° * | 2.42 ft 725 mm |

| Carry Height: Bucket Pin | 1.08 ft 321 mm |

| Dig Depth** | 0.33 ft 113 mm |

| Width: Bucket | 6.17 ft 1890 mm |

| Width: Tread Center | 4.67 ft 1420 mm |

| Turning Radius: Over Bucket | 14.17 ft 4327 mm |

| Width: Over Tires | 6.08 ft 1848 mm |

| Turning Radius: Outside of Tires | 12.92 ft 3925 mm |

| Turning Radius: Inside of Tires | 6.75 ft 2057 mm |

| Rack Angle at Full Lift | 56° 56° |

| Dump Angle at Full Lift | 45° 45° |

| Rack Angle at Carry | 51° 51° |

| Departure Angle - Degrees | 30° 30° |

| Articulation Angle - Degrees | 39° 39° |

| Operating Weight: Bucket ^ | 12632 lb 5730 kg |

| Tipping Load - Straight - ISO 14397-1 † | 9760 lb 4427 kg |

| Tipping Load - Full Turn - ISO 14397-1 † | 8225 lb 3731 kg |

| Operating Weight: Carriage and Tines ^^ | 12240 lb 5552 kg |

| Tipping Load - Straight † | 7748 lb 3514 kg |

| 80% of Tip: Firm and Level EN474-3 †† | 5211 lb 2364 kg |

| Note (1) | *Vary with bucket *Vary with bucket |

| Note (2) | **Vary with tire **Vary with tire |

| Note (3) | ^Horizontal Pin Lock Coupler (HPL-V) or Vertical Pin Coupler (SSL), 0.95 m3 (1.2 yd3) general purpose bucket. ^Horizontal Pin Lock Coupler (HPL-V) or Vertical Pin Coupler (SSL), 0.95 m3 (1.2 yd3) general purpose bucket. |

| Note (4) | ^^Horizontal Pin Lock Coupler (HPL-V) or Vertical Pin Coupler (SSL), class II carriage, 1220 mm (4 ft) tines (500 mm [20 in] load center). ^^Horizontal Pin Lock Coupler (HPL-V) or Vertical Pin Coupler (SSL), class II carriage, 1220 mm (4 ft) tines (500 mm [20 in] load center). |

| Note (5) | †Full compliance to ISO 14397-1 (2007) Sections 1 thru 6 (fork 500 mm [20 in] load center), which requires 2% verification between calculation and testing. †Full compliance to ISO 14397-1 (2007) Sections 1 thru 6 (fork 500 mm [20 in] load center), which requires 2% verification between calculation and testing. |

| Note (6) | ††Full compliance to EN474-3 and SAE J1197. ††Full compliance to EN474-3 and SAE J1197. |

| Note (7) | HPL-A weight, tipping and rated loads are within 1% of the HPL-V. HPL-A weight, tipping and rated loads are within 1% of the HPL-V. |

| Note (8) | Dimensions listed are for a machine configured with standard cab, heater, 20 km/h (12 mph), standard guarding, 80 kg (176 lb) operator, full fluids, SPT9EM 405/70 R18 tires and 0.95 m3 (1.2 yd3) general purpose bucket with bolt-on cutting edge or a class II fork carriage and tines (tire supplier variability can impact dimensions by 2%). Dimensions listed are for a machine configured with standard cab, heater, 20 km/h (12 mph), standard guarding, 80 kg (176 lb) operator, full fluids, SPT9EM 405/70 R18 tires and 0.95 m3 (1.2 yd3) general purpose bucket with bolt-on cutting edge or a class II fork carriage and tines (tire supplier variability can impact dimensions by 2%). |

| Note (9) | Note: Goodyear POWERLOAD® tires can add up to approximately 140 kg (305 lb) to the full turn tip load and reduce vertical height by approximately 25 mm (1 in) compared to SPT9. Note: Goodyear POWERLOAD® tires can add up to approximately 140 kg (305 lb) to the full turn tip load and reduce vertical height by approximately 25 mm (1 in) compared to SPT9. |

| Length: Front Axle to Front of Coupler | 3.5 ft 1065 mm |

| Tipping Load - Full Turn † | 6514 lb 2955 kg |

| Height - Ground to Cab | 8.08 ft 2468 mm |

| Height: Ground to Beacon** | 8.67 ft 2651 mm |

| Height: Ground Axle Center** | 1.58 ft 480 mm |

| Height - Ground Clearance | 1 ft 300 mm |

| Length - Overall with Bucket | 18.17 ft 5527 mm |

| Length: Rear Axle to Bumper | 4.58 ft 1391 mm |

| Length: Hitch to Front Axle | 3.58 ft 1085 mm |

| Length - Wheel Base | 7.08 ft 2170 mm |

| Clearance - Bucket at 45° | 7.83 ft 2391 mm |

| Clearance: Load over Height** | 9.5 ft 2902 mm |

| Clearance - Level Bucket | 9.92 ft 3028 mm |

| Height - Bucket Pin | 10.67 ft 3251 mm |

| Height: Overall** | 13.83 ft 4212 mm |

| Reach - Bucket at 45° | 2.67 ft 814 mm |

| Carry Height: Bucket Pin | 1.17 ft 345 mm |

| Dig Depth | 0.25 ft 85 mm |

| Width - Bucket | 6.17 ft 1890 mm |

| Width - Tread Center | 4.67 ft 1420 mm |

| Turning Radius - Over Bucket | 14.67 ft 4478 mm |

| Width - Over Tires | 6.07 ft 1848 mm |

| Turning Radius: Outside of Tires | 12.92 ft 3925 mm |

| Turning Radius - Inside Tire | 6.75 ft 2057 mm |

| Rack Angle at Full Lift | 51° 51° |

| Dump Angle at Full Lift | 50° 50° |

| Rack Angle at Carry | 46° 46° |

| Departure Angle - Degrees | 30° 30° |

| Articulation Angle - Degrees | 39° 39° |

| Operating Weight: Bucket ^ | 12863 lb 5835 kg |

| Tipping Load – Straight – ISO 14397-1 † | 8613 lb 3907 kg |

| Tipping Load – Full Turn – ISO 14397-1 † | 7220 lb 3275 kg |

| Operating Weight: Carriage and Tines ^^ | 12434 lb 5640 kg |

| Tipping Load - Straight † | 7359 lb 3338 kg |

| 80% of Tip: Firm and Level EN474-3 †† | 4970 lb 2254 kg |

| Note (1) | *Vary with bucket *Vary with bucket |

| Note (2) | **Vary with tire **Vary with tire |

| Note (3) | ^Horizontal Pin Lock Coupler (HPL-V) or Vertical Pin Coupler (SSL), 0.95 m3 (1.2 yd3) general purpose bucket. ^Horizontal Pin Lock Coupler (HPL-V) or Vertical Pin Coupler (SSL), 0.95 m3 (1.2 yd3) general purpose bucket. |

| Note (4) | ^^Horizontal Pin Lock Coupler (HPL-V) or Vertical Pin Coupler (SSL), class II carriage, 1220 mm (4 ft) tines (500 mm [20 in] load center). ^^Horizontal Pin Lock Coupler (HPL-V) or Vertical Pin Coupler (SSL), class II carriage, 1220 mm (4 ft) tines (500 mm [20 in] load center). |

| Note (5) | †Full compliance to ISO 14397-1 (2007) Sections 1 thru 6 (fork 500 mm [20 in] load center), which requires 2% verification between calculation and testing. †Full compliance to ISO 14397-1 (2007) Sections 1 thru 6 (fork 500 mm [20 in] load center), which requires 2% verification between calculation and testing. |

| Note (6) | ††Full compliance to EN474-3 and SAE J1197. ††Full compliance to EN474-3 and SAE J1197. |

| Note (7) | HPL-A weight, tipping and rated loads are within 1% of the HPL-V. HPL-A weight, tipping and rated loads are within 1% of the HPL-V. |

| Note (8) | Dimensions listed are for a machine configured with standard cab, heater, 20 km/h (12 mph), standard guarding, 80 kg (176 lb) operator, full fluids, SPT9EM 405/70 R18 tires and 0.95 m3 (1.2 yd3) general purpose bucket with bolt-on cutting edge or a class II fork carriage and tines (tire supplier variability can impact dimensions by 2%). Dimensions listed are for a machine configured with standard cab, heater, 20 km/h (12 mph), standard guarding, 80 kg (176 lb) operator, full fluids, SPT9EM 405/70 R18 tires and 0.95 m3 (1.2 yd3) general purpose bucket with bolt-on cutting edge or a class II fork carriage and tines (tire supplier variability can impact dimensions by 2%). |

| Note (9) | Note: Goodyear POWERLOAD® tires can add up to approximately 140 kg (305 lb) to the full turn tip load and reduce vertical height by approximately 25 mm (1 in) compared to SPT9. Note: Goodyear POWERLOAD® tires can add up to approximately 140 kg (305 lb) to the full turn tip load and reduce vertical height by approximately 25 mm (1 in) compared to SPT9. |

| Tipping Load - Full Turn † | 2818 kg 6212 lb |

| Length: Front Axle to Front of Coupler | 4.33 ft 1316 mm |

Üstünlükləri və xüsusiyyətləri

CONFIGURED FOR SUCCESS

- Cat® wheel loaders set the standard for productivity, fuel efficiency and operator comfort. The Cat 906 Compact Wheel Loader has a high torque C2.8 engine that works in conjunction with an intelligent hystat power train to deliver exceptional fuel efficiency. Dependent on regional requirements our engines meet U.S. EPA Tier 4 Final and EU Stage V emission standards with a clean emission module designed to manage itself so you can concentrate on the task at hand or emit equivalent to U.S. EPA Tier 3 and EU Stage IIIA.

ENJOY ALL DAY COMFORT

- All new cab is spacious, quiet and comfortable with all around 360° visibility to keep you productive throughout the day. Seat-mounted controls feature a multifunction joystick for lift and tilt functions with an integrated thumb operated speed range, forward/neutral/reverse (FNR) switch, trigger operated differential lock and constant flow. Optional fourth function joystick also available.

- Digital display with soft touch buttons for customized settings to easily control linkage and drive train to further enhance operator comfort and safety.

EFFICIENTLY POWERFUL

- Cat C2.8 engine provides a cleaner, quieter operation while delivering superior performance and durability through a high torque, low speed design. Caterpillar’s exclusive Intelligent Power Management system monitors operator input and available power to keep the machine working at peak efficiency.

- “Shift on the go” locking differentials and hydrostatic transmission provide smooth and powerful operation while increasing the efficiency of machine cycles. New Powertrain (Utility) Mode via the display enables right pedal machine operation giving further improved operator controllability of attachment RPM versus machine ground speed over creep control and inching pedal.

WORK MADE EASY

- All-in-one joystick to keep eyes on the work while maximizing operation of hydro-mechanical attachments with a state of the art pressure compensated electro-hydraulic system. Optimized Z-bar linkage for great performance and versatility with buckets that now have the DNA of the larger Cat loaders, such as curved side plates and a flat torque tube for parallel reference to the cutting edge.

CUSTOMIZE YOUR EXPERIENCE

- Work as one with your machine by customizing the controls. Operator can adjust machine responsiveness with the push of a button based on the attachment or application. Once customized, settings can be locked with “simplified mode” to ensure the machine is consistent and intuitive for every user.

- Machine security is enhanced with a standard keycode or optional Bluetooth® technology.

PURPOSE BUILT SPECIALTY MODELS

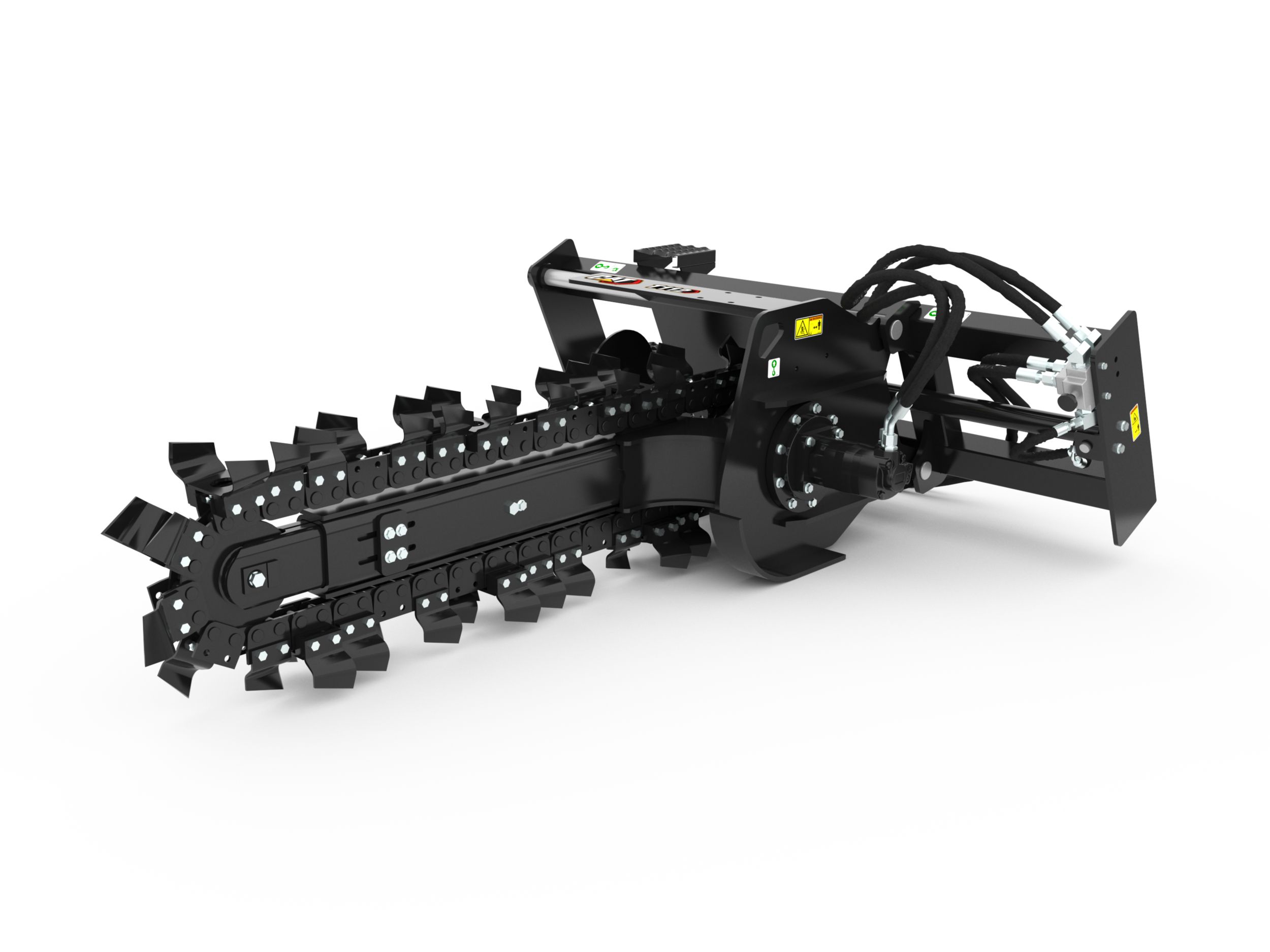

- Machines can be built to meet industry and application specific needs: Agriculture, General Construction, Industrial and Waste, Landscaping or Snow Removal.

- The 906 is availble with the following specific handler arrangements: Ag Handler and Waste Handler

AFTERMARKET AND SERVICES

- Range of services and aftermarket retrofits and upgrades available to keep your machine going and configured for your application.

- Service and maintenance parts available, including a range of self-service options (SSO) and dealer installed kits.

- Integrated Technology available to reduce service costs and maintenance.

SUSTAINABILITY

- The Cat® C2.8 engine meets U.S. EPA Tier 4 Final and EU Stage V emission standards.

- Engine Idle Shutdown Timer reduces fuel burn, greenhouse gas emissions and unnecessary idle time by shutting down the machine after a pre-set idling period.

- Remote Troubleshoot decreases maintenance time and keeps your machine running with maximum efficiency by allowing your Cat dealer to virtually test the machine while working. Once a problem is identified, a technician can fix it the first time, saving time and money.

- Remote Flash minimizes downtime and maintenance time while keeping your asset running with maximum efficiency. Alerts for machine updates are sent virtually from your Cat dealer and updates can be deployed without a dealer technician needing to be onsite.

- Advanced Electro Hydraulic System provides the optimum balance of power and efficiency while giving you the control you need for your precise jobsite requirements.

- Engine Demand Fan is hydraulically driven to provide machine cooling only when needed, improving fuel efficiency and reducing greenhouse gas emissions.

- Hydrostatic Transmission is an efficient way to transfer engine power to the wheels at low speeds versus a torque converter.

- Efficient HVAC regulates temperature control. No need to leave the machine running to cool the cab.

- Shift on the go transmission, means no need to stop so you keep your momentum.

Standart avadanlıq

-

ELECTRICAL

- Product Link™

- Service (Electronic Technician™)

- Lights, roading, front halogen

- Lights, rear stop and turn, LED

- Cab mounted fuse panel

- Battery disconnect switch

- Battery, heavy duty, 12V, 90Ah and 1,000 CCA

- Alternator, 100 amp sealed

-

HYDRAULICS

- Motor, single drive with dedicated implement and steering pumps

- Multi-function lift and tilt with loader arm float

- Joystick, single lever, single auxiliary roller

- Implement valve, pressure compensated

- Hystat displacement pump, infinitely variable

- Caterpillar HYDO™ Advanced 10 hydraulic oil

- Coupler/pin on attachment ready

- Demand cooling fan, hydraulically driven

- Dead engine lower, lift valve, manual

- Electro-hydraulic, fully proportional controls

- Hydraulic pilot shut off switch, in cab

-

OPERATOR ENVIRONMENT

-

Cab

– Doors (2), fixed glass

– Wipers, front and rear, full front coverage

– Windshield, front single piece

– Window, rear heated

– Radio ready, speakers and wiring

– Air vents, (4) screen, (7) directional

– Heating, mechanical control unit

– Sun visor, solid, front full width

– Interior light (incandescent)

- Seat, manual height adjustment, (cab) fabric with adjustable left arm rest, (canopy) vinyl

-

Joystick, seat mounted, standard multifunction

– FNR, auxiliary roller, speed range select, continuous flow, differential lock, horn

– Arm rest, padded right, multiple position vertical height

-

Display, analog and digital

– Gauges (2), hydraulic oil, engine coolant

– Digital with soft touch buttons – fuel level, speed range, speedometer, service hour meter, service/maintenance information, hydraulic and power train performance and aggressiveness settings, security passcode (multiple languages)

-

ROPS/FOPS certified canopy/cab

– 12V power outlets, interior/exterior

– Pedals, raised, foot, brake/inching, accelerator

– Lever, parking brake

– Cup holders (2)

– CB radio clip, phone holder

– Door release, internal (left and right)

– Hook, large, coat and hard hat

– Floormat, heavy duty, easy clean

– Mirrors, (2) external breakaway, (1) internal

– Operator station on isolation mounts

– Steering wheel, spinner knob, horn in center

– Seat belt, orange, retractable, 51 mm (2 in)

– Storage, personal (trays [3], seat pocket)

– Steering column, tilt adjusted

– Column mounted multi function control: lights, roading, wipers, self cancelling turn signals

– Quick coupler switch, in cab

-

Cab

-

OTHER

- Scheduled Oil Sampling (S·O·S℠) ports, engine oil and hydraulic oil

- Recovery hitch with pin

- Paint, Electro-Coat primer, gloss topcoat

- Machine lifting/tie down points

- Lockable, fuel cap, HVAC filters, nose cone

- Lockable main and side engine enclosures

- Loader arm safety brace

- Ground level easy access daily service points

- Fenders, front and rear

-

POWER TRAIN

- Fuel pump, priming (manual)/water separator/drain

- Engine oil, ECO drain tap and hose

- Engine, auto idle shutdown, hibernation mode

- Drive shaft, sealed for life, universal joints

- Coolant, extended life, –36° C (–33° F)

- Closed circuit breather

- Axles, heavy duty, frame mounted with outboard planetary reduction

- Air cleaner, two stage filter, with in cab audio/visual indicator on display

-

Cat C2.8 engine

– Diesel particulate filter (Fit for Life) or muffler (Dependent on regional regulations.)

– Fuel, diesel, ultra low or low Sulphur (Dependent on regional regulations.)

– Hydrostatic transmission, two speed, with inching function, “shift on the go”

– Power train mode, hystat

-

Emissions compliant, two options (Dependent on regional regulations.)

– U.S. EPA Tier 4 Final and EU Stage V

– U.S. EPA Tier 3 and EU Stage IIIA equivalent

Könüllü avadanlıq

-

ELECTRICAL

- Work tool wiring harness, (3) in cab switches

- Push to start

- Lighting packages, multiple; front, rear, engine bay (LED or HAL)

-

HYDRAULICS

- Quick disconnect auxiliary hydraulics

- Reversing fan

- Ride Control or load check valves (Dependent on regional regulations.)

- Connect under pressure and case drain

- Caterpillar Bio HYDO Advanced hydraulic oil

- Auxiliary flow, single standard (3) valve, single high flow (3) valve, dual high flow (4) valve

-

OPERATOR STATION

- USB ports (2), interior

- Sun visor, rear perforated

- Storage, lockable box or lockable cooled box

- Soft touch keypad options, 8 or 16 button

- Secondary display, front or rear view camera

- Seat packages; deluxe or premium

- Seat belt options, multiple

- Radio, FM or digital audio broadcast

- Phone holder, spring loaded

- Mirrors (2) electronically adjustable, heated external, plus lower parabolic mirror

- Joystick, seat mounted, multifunction

- Interior light, door activated

- FNR, twin auxiliary roller, continuous flow, differential lock, horn

- Doors, sliding windows (left and right)

- Air Conditioning, automatic temperature control (ATC)

-

OTHER

- Rotary sensors (snubbing, kickouts, parallel)

- Couplers, vertical (SSL), horizontal (HPL-V, HPL-A)

-

POWER TRAIN

- Power train mode, utility (includes keypad)

- Hydrostatic transmission, 3-speed, “shift on the go”, secondary steering and boosted brakes

- Fuel pump, priming (Higher regulated countries), electric (Dependent on regional regulations.)

- Creep and throttle lock function

- Cold start – jacket water heater, bypass valve

- Antifreeze, extended life coolant, –50° C (–58° F)